| Case Name |

Disaster of Chemical Plant at Flixborough |

| Pictograph |

|

| Date |

June 1, 1974 |

| Place |

Flixborough, UK |

| Location |

Cyclohexanone oxidation plant |

| Machinery |

Temporary bypass pipe for reactor and process pipe between separators |

| Overview |

The Flixborough Works of Nypro (UK) Ltd. were demolished at about 4:53 p.m. on Saturday June 1st. 1974, by an explosion of warlike dimensions which was the equivalent of 15 tonnes of TNT. Of those working on the site at the time, 28 were killed and 36 others suffered injuries. Outside the works injuries and damage were widespread. 53 people were recorded as casualties, while 1,821 houses and 167 shops and factories suffered damage to a greater or lesser degree. The plant at which the explosion occurred was part of a complex for the manufacture of nylon, jointly owned by Dutch State Mines (55%) and UK National Coal Board (45%). |

| Incident |

The reaction was cyclohexane with air under existence catalysis by 155°C, 125 lb/sq.in. (0.86 MPa), to a mixture of cyclohexanone and cyclohexanol that is usually known as KA (ketone/alcohol) mixture. The reaction took place in six vessels, each holding about 20 tonnes. One of the reactors, the No.5 reactor, developed a crack and was removed for repair. In order to maintain production, a temporary bypass pipe was installed between the No.4 reactor and the No.6 reactor. Because the reactors were mounted on a sort of staircase, this pipe was not straight but contained two bends. The pipe was 20in. (508 mm) in diameter, although the short pipes that were normally used to join the reactor together were 28in. (711 mm) in diameter. Bellows also 28 in.(711 mm) in diameter, were installed between each reactor, and these were left at each end of the temporary pipe. This temporary bypass pipe performed satisfactorily for two months after the plant was restarted on April 1st. However, the process pressure rose slightly, from 125 lb/sq.in. (0.86 MPa) to 129 lb/sq.in. (0.89 MPa ). The bending moment, caused by the action of this slight rise in pressure, was strong enough to tear the bellows. The temporary pipe acted to twist the flow, and the bellows were ruptured by shear stress. As a result of the rupture of the bellows, a great amount of cyclohexane escaped from the holes in the bellows and formed a cloud of cyclohexane vapour, which subsequently caused the explosion (Fig. 2). This explosion killed 28 men were and injured 36 men on site. The oxidation unit and neighboring units were destroyed and extensive damage was caused to the rest of the site. In particular, the company office block, about 100 m away, was destroyed. An initial investigation at the site found a "S" shape 20in. (508 mm) pipe assembly lying on the concrete plinth below its original position. It had jack-knifed completely at the lower mitre joint and apparently collided violently with the plinth after being projected forcibly downwards. Both of the bellows had torn away from the temporary pipe. They had also been torn off the reactor nozzles. Each of the bellows had disintegrated into a few large pieces, all of which were found in the vicinity of the failed pipe. In addition, the initial investigation revealed that a 50 in. (1270 mm) split had occurred in the bend in an 8 in. (203 mm) diameter stainless steel pipe joining two nearby separators. |

| Sequence |

The cyclohexane oxidation process was performed in a series of six reactors, each holding about 20tonnes. The reactors were about 12feet (3658mm) in diameter and 16feet (4877mm) high, and they were constructed of 1/2in. (13mm) mild steel, with internal cladding of 1/8in. (3mm) stainless steel (type 316L).

After fresh cyclohexane and recycle cyclohexane were scrubbed with water in a cooling scrubber, they were heated in a direct heat exchanger. Subsequently, both forms of cyclohexane were introduced into the No.1 reactor and oxidized to a mixture of cyclohexanone and cyclohexanol, usually known as KA (ketone/alcohol), with air under the existence of a catalyst, at 155degree C and 125lb/sq.in. (0.85 MPa).

At the end of March 1974, the No.5 reactor was found to be leaking, and an inspection showed a crack over 6feet (1830mm) long in the mild steel. Subsequent examination of the crack by Dutch State Mines (DSM) determined the cause of the failure to be nitrate stress corrosion cracking of the mild steel cladding. This nitrate stress corrosion cracking was believed to have been due to the practice of spraying nitrate-treated cooling water as a means for diluting and dispersing small leaks.

It was decided to remove the No.5 reactor, put in a temporary bypass pipe, and restart the plant. The bypass consisted of a dog-leg pipe from 20in. (508mm) diameter 304L stainless steel, installed between two expansion bellows that were attached to the 28in. (711mm) diameter nozzles after the reactor removal. The bypass was never closely inspected, although at operating temperatures and pressures, it was observed to lift off the scaffolding supports that were put in during the installation.

After the plant was restarted on April 1st.initially this temporary pipe connection functioned satisfactorily. However, on May 29th, a leak was found on sight glass, and the plant was shut down for repairs. An attempt to restart the plant was made at 4:00 a.m. on June 1st. More leaks were found, and after fixing these and restarting, the pressure was noted to rise more quickly than usual to 125lb/sq.in. (0.86MPa) gauge, well before the first reactor had reached operating temperature. Before any venting took place, however, another leak developed, the heating was stopped, and the pressure dropped to 64lb/sq.in. (0.44MPa) gauge.

The 7:00 a.m. to 3:00 p.m. shift fixed the leak and began warming the reactors up at 9:30 a.m., needing to vent only once at 11:30 a.m. when the pressure had reached 129lb/sq.in. (0.89MPa) gauge, but did not vent. The nitrogen stock for purging was found to be insufficient, however, and as a fresh delivery was not expected before midnight, the system was kept on "dry-cycling", i.e., recycling of hot cyclohexane under pressure but with no admission of air for reaction. At the end of the 7:00 a.m. to 3:00 p.m. shift, the temperatures in the reactor system had not leveled out.

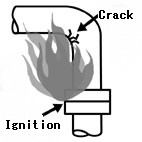

The temporary pipe was deformed in a "V" shape by bending stress at only slightly above operating pressure, and the bellows, the weak link in the chain, were torn away by shear stress. As a result, a massive vapor cloud was formed by the escape of cyclohexane from the holes of the ruptured 28in. (711mm) diameter bellows, and subsequent ignition caused the explosion to occur.

The explosion, which occurred 4:53 p.m., was estimated to have an equivalent force of at least 15tonnes of TNT. What happened on the final shift can never be known because all those in the control room were killed and all instrumentation and records were destroyed. The explosion also destroyed the oxidation units and neighboring units and caused extensive damage to the rest of the site.

The initial site investigation had revealed a 50in. (1270mm) split had occurred in the bend in an 8in. (203mm) diameter stainless steel pipe joining two nearby separators. A leak occurred at a flange on the non-return valve, located near this 50in. (1270mm) split. As a result, spontaneous combustion or a spray which were ignited by induced electrostatic charge, the result being a flame directed into the inside of an 8in. (203mm) bend.

After the explosion, a metallurgical investigation of the 8in. (203mm) line yielded considerable data concerning the effects of zinc embrittlement and creep cavitation at high temperatures on austenitic stainless steel.

At first, it was assumed that the assembly failed as a result of a small external explosion following the prior rupture of a nearby 8in. (203mm) line. However, this theory was rejected by the Court. |

| Cause |

After the No.5 reactor was removed for repair, a temporary bypass pipe was installed between the No.4 reactor and the No.6 reactor. The bypass pipe required an "S" shape, because the reactors were mounted on a sort of staircase.

The reason for why the bellows fractured by shear stress, was that the temporary pipe was installed without examining what the effect of a slight pressure rise on the bellows would be.

The workers who designed the temporary pipe were not professional engineers. The only calculations made were of the capacity of the assembly needed to carry the required flow. No calculations were done to ascertain whether the bellows or pipe would withstand the forces that would be exerted. No reference was made to the relevant British Standard or any other accepted standard. No reference was made to the designer's guide issued by the manufacturers of the bellows. No drawing of the pipe was made, other than in chalk on the workshop floor.

The support of the temporary pipe was a scaffolding structure upon which the pipe rested, without being fastened down. Therefore, the support structure could be provide not enough strength to withstand against bending stress.

The source of ignition was probably a natural gas reforming furnace some distance away. It was estimated that 30-50 tonnes of cyclohexane escaped in the 50 seconds that elapsed before ignition occurred.

Besides these details, the initial site investigation revealed that a 50in.(1270mm) split had occurred in the bend in an 8in. (203mm) diameter stainless steel pipe joining two nearby separators. The cause of this split is as follows. A leak occurred as a result of two loose bolts at a flange on the non-return valve, located near the 50in. (1270mm) split. This leak gave rise to an accumulation of oxidizable residues in the lagging and spontaneous combustion or a spray which was ignited by induced elctrostatic charges; the result being a flame directed into the inside of an 8in. (203mm) bend. It was assumed that the 50in. (1270mm) split occurred by zinc embrittlement and creep cavitation at high temperatures. This assumption was later confirmed by a metallurgical investigation showing that zinc embrittlement on austenitic stainless steel at a temperature of between 800 and 900 degree C could occur in a pipe under a stress of 3.21ton/sq.in. (48.8N/sq.mm) within a few seconds. The possible sources of zinc that could cause such an embrittlement attack were the galvanized stairways and the wire securing the lagging. Furthermore, it was shown that rapid creep cavitation of stainless steel may occur within minutes at temperatures of 950 degree C or more and under a stress of 4.7ton/sq.in. (71.4N/sq.mm).

In regard to the failure of the temporary pipe and an 8in. (203mm) pipe, it was supposed that the assembly failed as a result of a small external explosion following prior rupture of a nearby 8in. (203mm) pipe. However, the Court concluded that both phenomena occurred as a result of a sequence of improbabilities and coincidences. |

| Response |

Immediately after this disaster occurred, UK government ordered that a formal investigation be carried out by a Court of Inquiry, consisted of a panel of experts.

Experimental work, which included a full scale simulation was carried out at Flixborough. These tests showed that the bellows squired into on "S" shape at a pressure only slightly above the operating pressure.

Calculations of flow through the28 in. (711mm) diameter open nozzles of the two reactors supported the view that the release of the cloud of cyclohexane vapour of sufficient size to cause the disaster rapidly followed the collapse of the temporary pipe. It is almost impossible to prevent ignition of a leak the size of that which occurred at Flixborough. However, it is possible to locate and layout a plant so that injuries and damage are minimized if an explosion occurs. It was suggested that a diagram be made of the relation between the distance from the point of release and the size of the cloud (tonnes of hydrocarbon equivalent) at the plant containing materials that might explode. This diagram shows the restriction on design divided into six areas: A-F. For example, area A, the region within 20m from the point of release, should not contain any buildings at all. In area B, there should not be any other hazardous plants or site roads. In area C, there should not be any low pressure tanks. In area D, roofs of buildings should be independently supported and windows protected, and there should not be any public roads. In area E, there should not be any houses, and as for area F, there are no limitations on design. |

| Countermeasures |

Because the plant suffered wide-scale destruction, the first step of the countermeasure was to rebuild the plant according to the lessons learned from the disaster. In this case, it was necessary to consider the improvement of the production process. Because the production process was a high inventory process, if a leak occurred, the plant would suffer a great amount of damage. Therefore, if the production process were designed for inventory reduction, then it might be possible to minimize the damage.

In fact, the production process for manufacturing cyclohexanol was changed from the oxidation of cyclohexane to the hydrogeneration of phenol. However, this process is at least as hazardous. |

| Knowledge Comment |

It was well known to metallurgists that water contained nitrates causes stress corrosion cracking of mild steel. The decision that nitrate treated cooling water be sprayed on the top of the reactor, was made by persons who were not very knowledgeable. In fact, the decision was hardly known to the engineers.

No change in the operating condition outside the approved range should be made until they have been authorised by a professionally qualified manager.

After the reactor was removed, the temporary bypass pipe was designed and installed by mechanical engineers who were not professionally qualified because of the desire to quickly restore production.

No calculations were done to ascertain whether or not the bellows or the temporary pipe would be able to withstand the strains that would occur as a result of a slight rise in pressure. Also, the supports were not strong enough to withstand the bending stress of the pipe. Consequently, the bending moment caused by a slight rise in pressure was sufficient to cause the temporary pipe to tear the bellows.

Especially in plants that are treating hazardous materials, even relatively easy repairs or improvements of facilities should be made with thorough reference to the standards, and the design should be entrusted to professional engineers.

Occasionally, a large disaster can occur as a result of hot gas spouting to another piece of equipment, such as the gas that leaked from the 50in. (1270mm) split in the bend in an 8in. (203mm) diameter stainless steel pipe joining two nearby separators. So,it is necessary to consider methods for detecting and preventing leaks.

For plants containing materials that might explode, the safety of the plant layout and equipment location should be considered. For instance, no buildings should be within 20m of plant, and the construction of occupied buildings near the plant, should be strengthened.

On account of the high inventory of the production process at Flixborough, a large amount of cyclohexane escaped and caused a large scale explosion. If the plant had applied a low inventory process, a large scale explosion would not occur. It was not known why Flixborough adopted a high inventory process. Howevewr, when investigating the process operated at Flixborough, the output of the plant was found to be about 50,000tonnes/year KA. Assuming a linear velocity of 0.5m/s, it could all have passed through a pipe 1.6in. (40.6mm) in diameter. The actual pipe sizes ranged up to 28in. (711mm), so the cross section of the pipe, and thus the flow rate, was (28/1.6)^2 = 300 times greater than the theoretical minimum diameter required to support the plant output. |

| Sequel |

In the UK, the government set up an Advisory Committee on Major Hazards to consider the wider implications of the Flixborough explosion. It took about ten years for their recommendations to be made and to come into force. The recommendation of the committee resulted in the establishment of the CIMAH (Control of Industrial Major Account Hazards). The regulations have now been replaced by the COMAH (Control of Major Accident Hazards).

The plant changed its production process for manufacturing cyclohexanon and cyclohexanol from the oxidation of cyclohexane to the hydrogeneration of phenol. However, the rebuilt plant as closed down, after a few years, for commercial reasons. |

| Scenario |

| Primary Scenario

|

Ignorance, Insufficient Knowledge, Lacked Experience, Non-Regular Action, Change, Design Change, Poor Design, Shearing Stress, Usage, Maintenance/Repair, Pipe, Stainless Steel, Poor Inspection, Failure, Large-Scale Damage, Buckling, Explosion, Leakage, Ignition/Combustion, Usage, Operation/Use, Operation, Bad Event, Mechanical Event, Looseness of Pipe Flange, Internal Gas Leakage, Ignition/Combustion, Zinc Embrittlement

|

|

| Sources |

(1) Sir Fredrick Warner: Chemical Engineering Progress, Vol.71, No.9 (1975).

(2) S.J. Gould: Learning from Accident-3 rd Edition Chapter 8 Culf Professional Publishing.

|

| Number of Deaths |

28 |

| Number of Injuries |

89 |

| Multimedia Files |

Fig_2.View of fractured temporary pipe.

|

| Field |

Material Science

|

| Author |

SHINOHARA, Takanori (Toyo Eng. Corp. OB)

KOBAYASHI, Hideo (Yokohama National University)

|

|