| Case Name |

Rupture of a reactor caused by an abnormal reaction due to lowered cooling ability of the reactor on manufacturing a pharmaceutical intermediate |

| Pictograph |

|

| Date |

June 1990 |

| Place |

Wakayama prefecture, Japan |

| Location |

Chemical factory |

| Overview |

In 1990, an explosion occurred at a pharmaceutical intermediate manufacturing unit. After charging trimethyl phosphate, water, phosphorus oxychloride, and N-benzoyl-N-methylamine into the reactor, the temperature rose to 50 °C. Then, a mixture of tetrahydrofuran and dimethoxyethane was added during cooling. The temperature and inner pressure rose rapidly. Phosphoryl chloride and trimethyl phosphate ester became unstable, and started to rapidly decompose. As the reactor was not equipped with a pressure relief valve, an air vent valve was opened, but the reactor ruptured. |

| Incident |

There was an explosion at a pharmaceutical intermediate manufacturing unit. The reactor temperature rose due to decreased cooling capacity caused by corrosion of a reactor coolant jacket. The high temperature caused a decomposition reaction, increased the inner pressure of the reactor, and resulted in a rupture. |

| Processing |

Manufacture |

| Individual Process |

Reaction |

| Process Flow |

Fig2.Unit process flow

|

| Chemical Reaction |

Other |

| Substance |

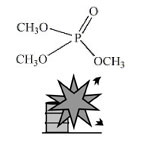

Trimethyl phosphate, Fig3 |

| Phosphorus oxychloride, Fig4 |

| Type of Accident |

Explosion |

| Sequence |

After charging trimethyl phosphate, water, phosphorus oxychloride, and N-benzoyl-N-methylamine into the reactor, the temperature was raised to 50 °C. Then, a mixture of tetrahydrofuran and dimethoxyethane was added during cooling. The temperature and inner pressure rose rapidly. As the reactor was not equipped with a pressure relief valve, an air vent valve was opened, but the reactor burst. |

| Cause |

Due to corrosion of the cooling jacket, cooling capacity was lowered and a reaction temperature rose, resulting in a runaway reaction. The rupture was thought to have occurred because the reactor was not equipped with a pressure relief valve for the increased inner pressure. Trimethyl phosphate might have become unstable, resulting in rapid decomposition due to a high temperature and pressure. |

| Knowledge Comment |

1. Attention should be paid to thermal stability of the chemicals in use. If they are unstable and likely to result in a runaway reaction, cooling capacity should be monitored.

2. If there is a possibility that an abnormal reaction can result in a pressure increase inside the reactor, a relief valve should be equipped even if the law does not require it. |

| Background |

1. Cooling capacity was assumed to have decreased gradually due to corrosion of the cooling jacket. Periodic checks of operation conditions should have found degradation of cooling capacity. Operation management seemed to be inadequate (insufficient operation management).

2. The reactor was not equipped with a pressure relief valve (inadequate process design).

3. Recognition of hazardous nature of the chemicals used might have been inadequate. |

| Reason for Adding to DB |

Example of rupture caused due to poor cooling ability reduced by corrosion |

| Scenario |

| Primary Scenario

|

Poor Value Perception, Poor Safety Awareness, Ignorance of Secure Detrioration of Cooling Ability, Insufficient Analysis or Research, Insufficient Prior Research, Insufficient Study of Reaction Danger, Planning and Design, Poor Planning, No Emwegency Blowdown, Usage, Maintenance/Repair, Oversight of Corrosion, Non-Regular Action, Inaction, No Action against Temperature Rising, Malfunction, Poor Hardware, Decline of Heat Transfer Capacity, Bad Event, Chemical Phenomenon, Abnormal Reaction, Failure, Large-Scale Damage, Rapture, Bodily Harm, Injury

|

|

| Sources |

Masamitsu Tamura. Msahide Wakakua. Explosion when manufacturing medical intermediate. Reaction danger- Accident case and analysis - p.127(1995)

|

| Number of Injuries |

2 |

| Physical Damage |

The reactor ruptured. |

| Multimedia Files |

Fig3.Chemical formula

|

|

Fig4.Chemical formula

|

| Field |

Chemicals and Plants

|

| Author |

YOSHINAGA, Jun (Graduate School of New Frontier Sciences, The University of Tokyo)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|

|