| Case Name |

White fumes generated from a tolylene diisocyanate (TDI) solution tank due to moisture contamination at a epichlorohydrin manufacturer |

| Pictograph |

|

| Date |

August 13, 1986 |

| Place |

Kawasaki, Kanagawa, Japan |

| Location |

Chemical factory |

| Overview |

n 1986, white fumes spouted from a manhole of a TDI tank at an ECH manufacturer in Kanagawa prefecture. The cause was contamination of water or impurities via a vent line. The tank had been converted and sufficient care was not taken for its new use at an ECH manufacturing plant. |

| Incident |

White fumes were generated from a tolylene diisocyanate (TDI) tank due to contamination of water. TDI is added to remove impurities on manufacturing epichlorohydrin (ECH). |

| Processing |

Storage |

| Substance |

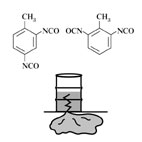

Tolylene diisocyanate (TDI), Fig2 |

| Type of Accident |

Leakage |

| Sequence |

In 1986, white fumes spouted from a manhole of a TDI tank at an ECH manufacturer in Kanagawa prefecture. Distillation and reaction processes of TDI production were stopped and cooling was performed with water. After decomposition was completed, the tank was opened and solid reaction products in the tank were removed. |

| Cause |

Water or impurities contaminated the contents of the tank via a vent line. |

| Response |

1. An emergency shutdown was carried out at a distillation section.

2. Water spraying on the tank.

3. Opening the tank to atmosphere.

4. Removal of solids in the tank. |

| Countermeasures |

The vent line was remodeled. |

| Knowledge Comment |

Generally, contamination or entrapment from a vent line is difficult to detect. Oxygen and water from atmosphere and gaseous substances from other tanks can only be prevented by using a nitrogen blanket at individual tank. |

| Background |

The structure of the vent line was not appropriate and allowed water or impurities to be drawn in. The accident occurred the first time TDI was introduced after conversion to secondhand use. It was suspected that conversion might have been carried out without careful consideration of TDI characteristics. |

| Reason for Adding to DB |

Example of inadequate previous study for secondhand usage |

| Scenario |

| Primary Scenario

|

Insufficient Analysis or Research, Insufficient Prior Research, No Grasping the Properties of Material, Organizational Problems, Inflexible Management Structure, Insufficient Information Transfer, Planning and Design, Poor Planning, Poor Design, Malfunction, Poor Hardware, Contamination of Foreign Material, Bad Event, Chemical Phenomenon, Abnormal Reaction, White Smoke Generation

|

|

| Sources |

High Pressure Gas Safety Inst. of Japan. Smoke generated from TDI solution tank due to contamination by moisture at Epichlorohydrin (ECH) manufacturer. Accident Examples of Petroleum Refinery and Petrochemical units. pp.163-164(1995)

|

| Multimedia Files |

Fig2.Chemical formula

|

| Field |

Chemicals and Plants

|

| Author |

YOSHINAGA, Jun (Graduate School of New Frontier Sciences, The University of Tokyo)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|