| Case Name |

Explosion of a dangerous material left near during repair work of a reduction reactor |

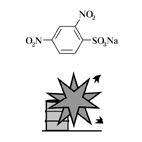

| Pictograph |

|

| Date |

October 28, 1949 |

| Place |

Oomuta, Fukuoka, Japan |

| Location |

Chemical factory |

| Overview |

On the sight where m-phenylenediamine was manufactured by a reduction reaction of m-dinitrobenzene, an explosion occurred. Sodium hydroxide spilled, and 2, 4-dinitro sodium sulphonate that had been left made contacted with sodium hydroxide and reacted. 2, 4-dinitro phenol sodium was generated. Cutting work started with an acetylene blowpipe for the repair, because a reduction reactor broke down. At that time, 2, 4-dinitro phenol sodium exploded by the heat of acetylene flames, and 10 workers got burnt. |

| Incident |

In the repair of a reduction reactor, steel plate cutting work started. An explosion occurred suddenly, and 10 workers got burnt. |

| Processing |

Manufacture |

| Individual Process |

Maintenance |

| Substance |

Sodium 2,4-dinitrobenzenesulfonate |

| Type of Accident |

Explosion |

| Sequence |

The repair work was carried out, as one of three reactors which manufactured m-phenylenediamine by the reduction of m-dinitrobenzene had broken down. Cutting work started with an acetylene blowpipe at the place 3m away from the broken down reactor. Just after the repair started, the material left in the floor suddenly exploded, and 10 workers were killed or injured. The material left was 90kg of 2, 4-dinitro sodium sulphonate in 4 wooden boxes. |

| Cause |

A 40% aqueous solution of sodium hydroxide spilled on 2, 4-dinitro sodium sulphonate that had been left. Both of them reacted, and 2.4-dinitrophenol sodium was formed. It is estimated that this was ignited by the heat of acetylene flames and exploded. Sodium hydroxide is used for the m-phenylenediamine manufacturing. |

| Countermeasures |

1. All hazardous chemicals are settled and removed in repair or construction work.

2. In the room where combustibles or explosive materials are handled and stored, a fire is not used. After these hazardous materials are removed, hot work is done.

3. Management such as the storage of chemicals is done thoroughly. |

| Knowledge Comment |

1. In or near the room where combustibles or explosive chemicals exist, hot work must be inhibited. Hot work should be done after these hazardous chemicals are removed.

2. As improper management of hazardous chemicals induces an accident, it is necessary to enhance the system that these can be severely managed. |

| Background |

1. Hot work was done at/near the place where combustibles or chemicals with explosion hazards were left.

2. 2, 4-dinitro sodium sulphonate was left near the place where sodium hydroxide used in the reduction reactor was handled, and there was a problem in storage and handling of chemicals. |

| Incidental Discussion |

It is an accident example of the postwar confused period, in 1949. It is possible that office discipline and measures for safety were insufficient. |

| Reason for Adding to DB |

Example of accident caused due to insufficient management and handling of chemical substances |

| Scenario |

| Primary Scenario

|

Organizational Problems, Poor Management, Habit/looseness, Poor Value Perception, Poor Safety Awareness, Inadequate Risk Recognition, Carelessness, Insufficient Precaution, Mannerism, Malicious Act, Rule Violation, Safety Rule Violation, Usage, Maintenance/Repair, Hot Work, Secondary Damage, External Damage, Explosion, Bodily Harm, Death, 8 person died, Bodily Harm, Injury, 2 person injured

|

|

| Sources |

Industrial accident case study association. Explosive substance and oxidizer. Industrial accident examples 1) the explosion. pp.86-87 (1971).

Japan Assoc. of Fire Science and Engineering chemistry fire committee. C.3.2 The nitro compound. Case 20. Chemistry fire examples (2). pp.74-75(1974)

Masamitsu Tamura. Wakakura Masahide. Explosion of the 2, 4-dinitrophenol sodium. The reaction danger. Accident case and analysis. p.68(1995).

|

| Number of Deaths |

8 |

| Number of Injuries |

2 |

| Field |

Chemicals and Plants

|

| Author |

OGAWA, Terushige (Graduate School of Environment and Information Sciences, Yokohama National University)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|

|