| Case Name |

Explosion of sodium picramate due to slight stimulation during handling |

| Pictograph |

|

| Date |

February 6, 1964 |

| Place |

Fukuyama, Hiroshima, Japan |

| Location |

Chemical factory |

| Overview |

The work to transfer the dehydrated and refined sodium picramate in a wooden barrel to another wooden barrel with a shovel was done. Explosion occurred during the work, surrounding combustibles caught fire, and the fire extended all over the first floor. It is considered that the ignition source was a spark by the collision between metal fittings in the upper part of the wooden barrel and the iron band of another barrel, or electric discharge of a few nails which stuck out in the barrel. The fundamental knowledge in handling sensitive materials like the explosives seemed to be lacking. |

| Incident |

Operators transferred the dehydrated and refined sodium picramiate from wooden barrel to the storage bag on the weighing instrument with a shovel. The sodium piramate exploded when they moved the sodium piramate that remained in the wooden barrel to another wooden barrel. |

| Processing |

Manufacture |

| Individual Process |

Other |

| Substance |

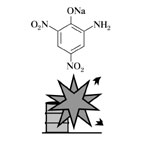

Sodium picramate, Fig2 |

| Type of Accident |

Explosion, fire |

| Sequence |

Operators put the dehydrated and refined sodium picramate in the wooden barrel to storage bag on the weighing instrument with the shovel. They transferred the remaining sodium picramate in the barrel to another wooden barrel by holding the first barrel, because the quantity of remains became too small and the bottom of the first barrel was seen. Sodium picramate suddenly exploded at that time, and fire broke out, The flame spread instantaneously, and the fire extended all over the first floor. Three operators died, and four operators got injured. |

| Cause |

1. They transferred the remains of sodium picramate in the first barrel to another barrel with holding up the first wooden barrel. As this work was done in an unstable posture, it is presumed that metal fittings of the upper part of the barrel struck the iron band of another wooden barrel, causing sparks, and the sodium picramate ignited and exploded.

2. The other presumption is as follows: A few nails stuck out in the barrel were electrified with static electricity, and discharged. |

| Countermeasures |

1. Improvement in the work method.

2. Education and training on the handling of sensitive materials.

3. Ignition hazard of the sodium picramate is sufficiently studied. |

| Knowledge Comment |

1. The unstable or unnatural posture like holding up heavy goods is not adequate for the work handling energetic materials like explosives.

2. In the work handling energy materials like explosives, hard materials as iron should not be exposed in the instruments. |

| Background |

1. Dried sodium picramate is sensitive and close attention is necessary, when such dangerous material is handled. However, it is assumed that the manager and employees lacked basic knowledge in handling the energetic materials like explosives. For example, it is common sense that hard materials like iron should not be exposed in the devices for handling sensitive materials.

2. It is presumed that ignition hazard of the sodium picramate was not sufficiently studied. |

| Reason for Adding to DB |

Example of explosion accident caused due to slight stimulation of a sensitive material |

| Scenario |

| Primary Scenario

|

Ignorance, Insufficient Knowledge, Insufficient Experience/Study, Poor Value Perception, Poor Safety Awareness, Inadequate Risk Recognition, Planning and Design, Poor Planning, Poor Planning of Sub-divide, Regular Movement, Dangerous Movement, Rambling, Bad Event, Chemical Phenomenon, Abnormal Reaction, Secondary Damage, External Damage, Fire, Bodily Harm, Death, 3 person died, Bodily Harm, Injury, 4 person injured

|

|

| Sources |

Japan Assoc. of Fire Science and Engineering, Chemistry fire committee, C.3.2 The nitro compound. Case 205, Chemistry fire examples (2), p.78 (1974)

Masamitsu Tamura, Masahide Wakakura, Ignition of the sodium picramate. reaction hazard -Accident case and analysis - p.74 (1995)

|

| Number of Deaths |

3 |

| Number of Injuries |

4 |

| Financial Cost |

¥ 1.4 million. (reaction dangerous-accident case and analysis-) |

| Multimedia Files |

Fig2.Chemical formula

|

| Field |

Chemicals and Plants

|

| Author |

OGAWA, Terushige (Graduate School of Environment and Information Sciences, Yokohama National University)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|

|