| Case Name |

Burst of a distillation drum due to abnormal reaction of 2,2'-dinitrodiphenylamine with impurities |

| Pictograph |

|

| Date |

July 22, 1964 |

| Place |

Ichikawa, Chiba, Japan |

| Location |

Chemical factory |

| Overview |

The burst occurred during distillation of crude 2.2'-dinitro diphenylamine in the stainless distillation drum. The sodium hydroxide remained due to inadequate water rinsing after alkali cleaning in the previous process. Unexpected reaction with the sodium hydroxide occurred during distillation, and the temperature in the column started rising abnormally. Heating was stopped, but the cooler and the lid burst, and the contents became a yellow mist and was scattered. |

| Incident |

The distillation temperature rose abnormally while distilling crude 2.2-dinitrodiphenilamine in the stainless steel distillation drum. Though heating was stopped, the cooler and the lid burst, then the contents were scattered as a yellow mist. |

| Processing |

Manufacture |

| Individual Process |

Distillation |

| Process Flow |

Fig2.Unit process flow

|

| Substance |

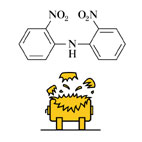

2,2'-dinitrodiphenylamine, Fig3 |

| Type of Accident |

Burst, leakage |

| Sequence |

Crude 2.2'-dinitrodiphenylamine was distilled in the stainless distillation drum. It was confirmed that the temperature in the drum started rising abnormally at 130 °C and rose to 200 °C. Therefore, heating was stopped. As observing from the outside, the cooler and the lid burst, and the contents became a yellow mist and were scattered. |

| Cause |

Sodium hydroxide remained in the crude 2.2'-dinitrodiphenylamine because rinsing after alkali cleaning was inadequate. It is presumed that contents reacted with sodium hydroxide unexpectedly under distillation and the temperature rose abnormally. |

| Countermeasures |

1. Improvement in the operation manual.

2. Education and training of operating skill and countermeasures in emergencies. |

| Knowledge Comment |

1. In the distillation, impurities may cause an abnormal reaction.

2. The water rinsing can not remove the constituent included in the equivalent solution. The required concentration should be made clear, and some measures should be taken. |

| Background |

The water rinsing is a dissolving separation, so a technical skill is necessary to remove an objective substance completely, for example multistage rinsing. It is presumed that neither the design nor the management of rinsing was insufficient. |

| Reason for Adding to DB |

Example of accident caused due to reaction with impurities during the distillation process |

| Scenario |

| Primary Scenario

|

Poor Value Perception, Poor Safety Awareness, Insuficient Education/Training for Safety, Carelessness, Insufficient Understanding, Inadequate Risk Recognition, Planning and Design, Poor Planning, Poor Design, Regular Movement, Careless Movement, Insufficient Rinsing, Bad Event, Chemical Phenomenon, Abnormal Reaction, Failure, Large-Scale Damage, Rapture

|

|

| Sources |

Masamitsu Tamura, Masahide Wakakura, Explosion of 2.2'-dinitrodiphenylamine, Reaction danger -Accident case and analysis -, p.162(1995).

|

| Financial Cost |

¥ 29,000 |

| Multimedia Files |

Fig3.Chemical formula

|

| Field |

Chemicals and Plants

|

| Author |

OGAWA, Terushige (Graduate School of Environment and Information Sciences, Yokohama National University)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|

|