| Case Name |

Explosion of azobisisobutyronitrile (AIBN) caused due to overheat from excessive tightening of the gland packing of a drier |

| Pictograph |

|

| Date |

July 7, 1967 |

| Place |

Sakaide, Kagawa, Japan |

| Location |

Chemical factory |

| Overview |

An Explosion occurred when drying 2, 2'-azobisisobutylnitrile (AIBN) (powder with 12% water). The explosion was induced by overheating of the agitator impeller shaft. The overheating was caused by friction from excessively tightened gland packing at a shaft-seal. It might have been prevented by communicating operation methods and daily hazard predicting activities. |

| Incident |

An explosion occurred in a factory manufacturing a foaming agent. A vacuum dryer exploded during the drying operation for azobisobutyronitrile (AIBN) powder with 12% water. |

| Processing |

Manufacture |

| Individual Process |

Drying and desiccation |

| Process Flow |

Fig2.Unit process flow

|

| Substance |

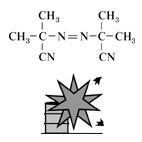

2,2'-azobisisobutyronitrile, Fig3 |

| Type of Accident |

Explosion |

| Sequence |

100 kg of AIBN with 12-13% moisture was dried in a horizontal hot water heating vacuum dryer by reducing the internal pressure to about 50 mmHg abs, using 45°C warm water in the jacket, and agitating at 71 rpm with an impeller. Since the drying had almost come to an end, the steam valve for heating warm water for the jacket was closed. An explosion occurred after about 10 minutes. |

| Cause |

As the gland packing of the agitator impeller shaft at the end plate was tightened excessively, the AIBN that penetrated the gland packing at the end plate was overheated, causing thermal decomposition of adjacent AIBN. Then, the heat of decomposition assisted self-accelerated decomposition of AIBN, led to the explosion. |

| Countermeasures |

Unification of fastening tightness of gland packing for the shaft-seal seems to be necessary.

The problem of overheating caused by tightening of the seal of gland packing is very common. Monitor and alarm systems for detecting temperature and/or motor output might be necessary. |

| Knowledge Comment |

Gland packing allows a small leak. When there is a leak which affects the degree of vacuum, the gland packing should be changed or should be increased if there is a space rather than strengthening tightening. |

| Background |

Poor recognition about the hazardous decomposition of AIBN during maintenance led to excessive tightening of the gland packing, which promoted overheating. |

| Reason for Adding to DB |

Example of explosion caused due to lack of hazard prediction |

| Scenario |

| Primary Scenario

|

Ignorance, Insufficient Knowledge, Insufficient Study/Experience, Organizational Problems, Inflexible Management Structure, Inadequate information Communication, Usage, Maintenance/Repair, Repair, Bad Event, Mechanical Event, Heat Generation by Over-Tightenning, Bad Event, Chemical Phenomenon, Abnormal Reaction, Secondary Damage, External Damage, Explosion, Bodily Harm, Injury, 8 person injured, Loss to Organization, Economic Loss, Reactor severe damaged

|

|

| Sources |

Japan Assoc. of Fire Science and Engineering, Chemical fire committee, A.7.2, Organic foam chemicals (foaming agent). Case 184, Examples of chemical fires (2), pp.18-19(1974)

Masamitsu Tamura, Masahide Wakakura, Azobisisobutyronitrile explosion. Reaction danger, -Accident case and analysis- p.164(1995)

|

| Number of Injuries |

8 |

| Physical Damage |

A dryer was seriously damaged. |

| Multimedia Files |

Fig3.Chemical formula

|

| Field |

Chemicals and Plants

|

| Author |

ARAI, Mitsuru (Environmental Science Center, The University of Tokyo)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|

|