| Case Name |

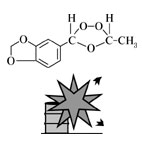

Explosion of ozonide caused due to neglect of a reaction from improper temperature measurement |

| Pictograph |

|

| Date |

August 15, 1969 |

| Place |

Hiratsuka, Kanagawa, Japan |

| Location |

Chemical factory |

| Overview |

A reaction to manufacture ozonide by oxidation using ozone was carried out, and it was interrupted while it had not yet finished. The reaction was restarted after 20 hours, and an explosion occurred near the end of the reaction. The ozonide was unstable, and it was decomposing during the interruption and accumulating heat. As the temperature recorder in the reactor failed, a bar-type thermometer was used instead, but temperature conditions could not be grasped. |

| Incident |

A reaction to generate ozonide by the ozonation of isosafrole was carried out with keeping the reactor inside temperature at 3°C. The reaction was interrupted when the yield of ozonide reached about 20-25%, and the reaction was re-started after 20 hours. An explosion occurred near the end of the reaction. |

| Processing |

Manufacture |

| Individual Process |

Reaction |

| Process Flow |

Fig2.Unit process flow

|

| Chemical Reaction |

Oxidation |

| Chemical Equation |

Fig3.Chemical reaction formula

|

| Substance |

Isosafrole ozonide, Fig4 |

| Isosafrole. Fig5 |

| Type of Accident |

Explosion |

| Sequence |

Isosafrole (150 kg) was charged into a 600 L stainless reactor, and ozone was added to oxidize it while the internal temperature was kept at 3 °C. The reaction was interrupted when the yield of ozonide reached about 20-25%, and the reaction was restarted after 20 hours. The explosion occurred near the end of the reaction, the internal pressure of the reactor rose, and the lid of the reactor was blown 300 m away. |

| Cause |

As the temperature recorder of the reactor failed, the reaction temperature was measured with a bar-type thermometer every hour, but it was impossible to sufficiently grasp the temperature inside of the reactor. Therefore, heat of decomposition of ozonide accumulated, and decomposition of ozonide might have progressed at a higher-temperature part like a runaway reaction. |

| Countermeasures |

1. In manufacturing with exothermic danger, continuous measurement of the temperature must be done. If possible, more than two sets of thermometers should be prepared taking account of thermometer trouble and/or reliability of the measured value, and a high temperature alarm should be equipped.

2. Safety valves for a sudden pressure rise and an emergency cooling system to keep the safety are necessary. It is also necessary to carry out education of workers and review the operation manual.

3. Safety countermeasures are necessary if a reaction left unfinished. |

| Knowledge Comment |

Grasp and assessment of the hazard are indispensable, when the potentially hazardous material is handled. It is necessary to keep the operation procedure that was acquired from the evaluation. |

| Background |

1. The reaction was neglected before the reaction finished without grasping the hazardous properties of the reaction product. Ozonide is chemically unstable, exothermic decomposition occurs if it is left for a long time in a reactor, and gas is generated as a decomposition product. Even if the hazardous properties of ozonide were not known, it would be difficult to believe that the ozonide was a stable material from the structural formula. The accident would not have occurred if the correct handling method was understood from an investigation of physical properties at that time, and the operator was instructed properly.

2. Operation with improper temperature measurement should not be allowed. It seemed that no agitation was carried out while the reaction was interrupted, and the measured temperature in the vessel without agitation cannot show the representative temperature of the reactor. Without agitation, the temperature can only be measured at just adjacent area of the thermometer.

Considering the above, there seemed to be a management problem. |

| Reason for Adding to DB |

Example of explosion caused due to a lack of basic knowledge on material hazards |

| Scenario |

| Primary Scenario

|

Organizational Problems, Poor Management, Slackness of Management, Poor Value Perception, Poor Safety Awareness, Inadequate Risk Recognition, Insufficient Analysis or Research, Insufficient Prior Research, Insufficient Danger Evaluation, Malicious Act, Rule Violation, Safety Rule Violation, Bad Event, Chemical Phenomenon, Abnormal Reaction, Secondary Damage, External Damage, Explosion, Loss to Organization, Economic Loss, Reactor Damaged

|

|

| Sources |

Masamitsu Tamura, Masahide Wakakura, Ozonide explosion. Reaction hazard,- Accident case and analysis -p.55(1995)

Ministry of Labor, Industrial Safety and Health Department, Safety section, Explosive decomposition of reaction intermediate ozonide. Safety of batch process. pp.46-47(1987)

Tetsuzo Kitagawa, Explosion caused by decomposition of ozonide. Analysis of explosion hazard, pp.260-261(1980).

|

| Physical Damage |

A reactor was damaged. |

| Multimedia Files |

Fig4.Chemical formula

|

|

Fig5.Chemical formula

|

| Field |

Chemicals and Plants

|

| Author |

ARAI, Mitsuru (Environmental Science Center, The University of Tokyo)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|

|