| Case Name |

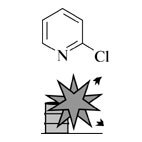

Explosion of 2-chloropyridine-N-oxide left as a distillation residue |

| Pictograph |

|

| Date |

August 14, 1973 |

| Place |

Atsugi, Kanagawa, Japan |

| Location |

Chemical factory |

| Overview |

Large-scale trial manufacture of 2-chloropyridine-N-oxide was carried out. Reduced-pressure distillation was carried out after the synthesis reaction, and the residue was left in the bottom of the distillation kettle. A fire occurred next morning due to insufficient grasp of the characteristics of materials and inadequate cooling equipment. |

| Incident |

Large-scale trial manufacturing of 2-chloropyridine-N-oxide was carried out. Acetic acid and water were removed by distillation of the reaction product, which was an oxidant of 2-chloropyridine with hydrogen peroxide. While the distillation residue, which was mainly 2-chloropyridine-N-oxide, was left in the bottom, a burst of the distillation kettle and a fire occurred. |

| Processing |

Manufacture |

| Individual Process |

Distillation |

| Process Flow |

Fig2.Unit process flow

|

| Substance |

2-chloropyridine, Fig3 |

| Acetic acid, Fig4 |

| Hydrogen peroxide, Fig5 |

| Type of Accident |

Rupture, Fire |

| Sequence |

1. 2-chloropyridine was charged into a distillation kettle with an inside volume of 3 kL, which was also a reactor. Glacial acetic acid was used as a solvent, and it was oxidized by a 35% aqueous solution of hydrogen peroxide in the presence of 98% concentrated sulfuric acid.

2. Acetic acid and water were removed by reduced-pressure distillation. The produced 2-chloropyridine-N-oxide, which was the main component of the residue, was left in bottom of the kettle.

3. Next morning, the contents spouted out from a safety valve and a crack of a glass tube of a looking-glass of the distillation line. It was ignited by some ignition source and a fire occurred. |

| Cause |

The cooling capacity of the jacket at the bottom became almost zero, because the jacket was only filled with water. Therefore, decomposition of the contents of the distillation kettle gradually progressed, which became a rapid decomposition reaction due to heat accumulation. It was proved that 2-chloropyridine-N-oxide was an unstable material in which an exothermic decomposition reaction occurred at 120-130 °C after the accident. As for the decomposition reaction, since the substance is basic and easily forms hydrochloride, the main reaction seemed to be a hydrochloride-generating reaction, at least in the initial exothermic process. |

| Knowledge Comment |

1. Jackets at the reactor do not function, either in terms of cooling or heating, if a cooling or heating medium does not continue flowing.

2. Grasping and assessing hazards are indispensable when a potentially hazardous material is handled. |

| Background |

1. It was proved that 2-chloropyridine-N-oxide was an unstable material in which an exothermic decomposition reaction occurred at 120-130 °C. It was handled without knowing its physical properties. It should have been studied by investigations and experiments beforehand.

2. The volume of the jacket was very small and the heat capacity was also small, therefore, the temperature rose at once. Moreover, effective heat transfer through the jacket surface could be achieved by flowing objects at both sides of the jacket wall. It is important to have fundamental knowledge of heat transfer. |

| Reason for Adding to DB |

Example of explosion caused due to lack of basic knowledge on material hazards |

| Scenario |

| Primary Scenario

|

Insufficient Analysis or Research, Insufficient Prior Research, Insufficient Grasping of Prpperty, Poor Value Perception, Poor Safety Awareness, Inadequate Risk Recognition, Planning and Design, Poor Planning, Poor Design, Bad Event, Chemical Phenomenon, Abnormal Reaction, Secondary Damage, External Damage, Explosion, Bodily Harm, Injury, 1 person injured

|

|

| Sources |

Masamitsu Tamura, Masahide Wakakura, Explosion and fire of 2-chloropyridine -N- oxide distillation kettle residue. Reaction danger -Accident case and analysis - p.62(1995)

Ministry of Labor, Industrial Safety and Health Department, Safe section, Explosion and fire of 2-chloro pyridine-N-oxide distillation residue. Safety of batch process, pp.50-51(1987)

|

| Number of Injuries |

1 |

| Physical Damage |

A distillator was damaged. |

| Multimedia Files |

Fig3.Chemical formula

|

|

Fig4.Chemical formula

|

|

Fig5.Chemical formula

|

| Notes |

In accident case reports of chloropyridine-N-oxide, there is a report of an explosion under reduced-pressure distillation after a reaction. |

| Field |

Chemicals and Plants

|

| Author |

ARAI, Mitsuru (Environmental Science Center, The University of Tokyo)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|

|