| Case Name |

Spouting of hot cleaning liquid from a manhole opened for inspection at an acrylamide purifying column |

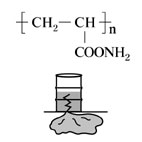

| Pictograph |

|

| Date |

October 9, 1992 |

| Place |

Takaishi, Osaka, Japan |

| Location |

Chemical factory |

| Overview |

Hot liquid spouted out on temporary opening of the acrylamide purifying column. When the last bolt was taken off to open the lower manhole of the column, the hot liquid spouted out from the column, and a worker received a burn. Steaming was carried out for opening, but a solid that would have been polymerized during the operation blocked the manhole.

The major cause was a mistake in the operating instructions. |

| Incident |

Hot liquid spouted out from an acrylamide purifying column when it was opened for inspection. An acrylamide polymer and hot washing water that remained in the column spouted out. One subcontract worker died and another was slightly injured. |

| Processing |

Manufacture |

| Individual Process |

Maintenance |

| Substance |

Acrylamide polymer |

| Type of Accident |

Leakage |

| Sequence |

On October 8th, 1992, the day before the accident occurred, operators decided to open an acrylamide purifying column on the next day, the 9th, because the feed rate to the column had decreased.

In preparation for the open inspection, the liquid in the column was drained, water washing started, and finished on the morning of the 9th.

All bolts of the manhole at the lower part of the column were loosened, the manhole was opened a little to check whether liquid in the column flowed out.

When the last bolt was taken off, the hot washing water spouted out due to residual pressure. |

| Cause |

1. Pressure remained in the column when the manhole was opened. Opening of a manhole has to be executed after pressure is released completely.

2. Liquid draining and water washing were not completed. Liquid possibly remained even, though liquid was drawn-off from the lowest point of the piping and the column, because the treated materials were very easy to clog. As a result, a polymer that might be generated during the operation blocked the manhole. It did not flow out when the manhole was slightly open, but blew off due to residual pressure when the last bolt was taken off. |

| Countermeasures |

Regulations for allotment of work should be reviewed so that there are no discrepancies in operating instructions. If there is a discrepancy in directions, the work should not be allowed.

To detect a polymerization reaction, a thermometer should be equipped at the bottom of the column, and a depressurizing device should be installed. |

| Knowledge Comment |

When any risk in work can be predicted, not only a person in charge of maintenance and also a person in charge of operation of the plant should watch the operation.

Where a system is easily blocked, pressure should be measured at more than two points, not one. |

| Background |

Although the manufacturing section instructed that it was very dangerous work, the maintenance section misunderstood the hazard level. Therefore, the meeting before the work, prevention measures for scattering, and wearing protective gear were not conducted, though they were all supposed to be done. This column open work does not seem the first time, so the person in the maintenance section should have been aware of the danger.

The distillation column is basically considered to be blocked easily by polymers. Even though the workers knew this, the pressure was not released completely. Furthermore, they should have measured the pressure at more than two points (one point is not enough) and checked whether pressure still remained in the column. |

| Incidental Discussion |

The reason why the pressure remained in the column is not certain, as no details were written about it in reports. It is an essential premise that pressure is measured before opening a manhole, and then the pressure may be equalized with atmospheric pressure or at least one valve might have been opened. Did pressure remain only at the lower part of the manhole, as a residue was a polymer ? |

| Reason for Adding to DB |

Example of hot water spouting accident caused due to residual pressure from opening of a vessel |

| Scenario |

| Primary Scenario

|

Poor Value Perception, Poor Safety Awareness, Inadequate Safety Countermeasure, Misjudgment, Misunderstanding, Poor Detail Planning, Usage, Maintenance/Repair, Repair at Open to Atmosphere, Bad Event, Chemical Phenomenon, Pluggng, Secondary Damage, External Damage, Leakage, Bodily Harm, Death, Bodily Harm, Injury

|

|

| Sources |

The high pressure gas safety institute of Japan, High-pressure gas protection overview, pp.268-269, 277(1993)

High pressure Gas Safety Inst.of Japan, Acrylamide manufacturing plant, Washing liquid spouted out from the acrylamide purifying column, Accident Examples of Petroleum refinery and Petrochemical units. pp.208-209(1995)

|

| Number of Deaths |

1 |

| Number of Injuries |

1 |

| Field |

Chemicals and Plants

|

| Author |

WADA, Yuji (National Institute of Advanced Industrial Science and Technology)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|

|