| Case Name |

Fire due to spontaneous polymerization of vinyl acetate during long-term storage |

| Pictograph |

|

| Date |

August 3, 1971 |

| Place |

Ogaki, Gifu, Japan |

| Location |

Chemical factory |

| Overview |

In August, 1971. At a synthetic resin plant, a vinyl acetate monomer without a polymerization inhibitor was stored for two months.

Therefore, spontaneous polymerization progressed, and the drum exploded, causing a fire.

The temperature rise of the drum could not have been detected beforehand, because temperature inspection for the tank was insufficient.

As the raw material prepared for a reaction is adjusted so that the reaction progresses easily, its reactivity often differs from usual. |

| Incident |

A vinyl acetate monomer had been stored in a measuring drum (1000 L, made of aluminum) at a synthetic resin plant that used vinyl acetate as raw material. Two months later, the vinyl acetate blew off from the gauge of the measuring drum, ignited and burned. In addition, the drum ruptured.

Two persons who tried to extinguish the fire were injured.

Refer to Fig2. |

| Processing |

Storage |

| Process Flow |

Fig2.Unit process flow

|

| Substance |

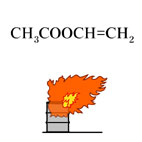

Vinyl acetate, Fig3 |

| Type of Accident |

Leakage, fire, rupture |

| Sequence |

About 940 L of vinyl acetate monomer had been stored in a measuring drum (1000 L. made of aluminum).

Two months later, polymer blew off from the gauge of the measuring drum, and was ignited by static electricity.

The drum was overheated, the pressure increased, and the drum ruptured.

Two persons who tried to extinguish the fire were injured. |

| Cause |

A vinyl acetate monomer was stored without a polymerization inhibitor.

Therefore, spontaneous polymerization progressed, and a rapid polymerization reaction was caused by the accumulation of heat.

The temperature rise of the drum was not detected because the temperature inspection of the drum was insufficient. |

| Response |

Fire extinguishing work was carried out. |

| Countermeasures |

During storage or transfer, a polymerization inhibitor is added to a monomer.

It is stored in a cool and dark place.

Contamination by impurities that promote polymerization is prevented.

A thermometer and a water sprinkler for cooling are installed in the tank.

Suitable de-pressurizing equipment and a pressure safety valve are installed.

Sufficient maintenance checks are performed.

The concentration of the polymerization inhibitor and the polymer in a monomer are analyzed periodically.

Long-term storage is avoided by planned storage. |

| Knowledge Comment |

The safety countermeasures, such as adding a polymerization inhibitor, are required in storing a substance with reaction hazards, such as self-polymerization.

When the polymerization inhibitor is removed prior to a reaction, the inhibitor should be removed just before use.

Large-scale and long-term storage of chemicals with reaction hazards should be avoided. |

| Background |

Why was a vinyl acetate monomer stored without a polymerization inhibitor for two months at a factory that deals with vinyl acetate?

The company and the factory must have had the full knowledge of the natural spontaneous polymerization of vinyl acetate.

Its storage must have been forgotten as it was stored in a measuring drum which is not the proper storage equipment, and temperature checks on the tank were insufficient.

There was a management problem in the background of the accident. |

| Incidental Discussion |

This is a mysterious accident. Storage was in a measuring drum. Substances in a measuring drum are usually charged immediately to the following step, for example, reaction. Temperature is not controlled and as much as 973 L of vinyl acetate monomer is put into a 1000 L drum. Its storage was surely forgotten. |

| Reason for Adding to DB |

Example of a fire during long-term storage without a polymerization inhibitor |

| Scenario |

| Primary Scenario

|

Organizational Problems, Poor Management, Slackness of Management, Poor Value Perception, Poor Safety Awareness, Inadequate Risk Recognition, Ignorance, Insufficient Knowledge, Insufficient Study, Planning and Design, Poor Planning, Poor Storage Plan, Usage, Transport/Storage, Wrong Storge Measure, Bad Event, Chemical Phenomenon, Abnormal Reaction, Secondary Damage, External Damage, Fire/Rapture, Bodily Harm, Injury, 2 person injured, Loss to Organization, Economic Loss, Tank Breakage

|

|

| Sources |

Masamitsu Tamura, Masahide Wakakura, Ignition by spontaneous polymerization of vinyl acetate. Reaction danger-Accident cases and analysis- p.20,(1995)

Ministry of Labor. Safety and Health Department. Safe section, Fire caused by the spontaneous polymerization heat of vinyl acetate in a tank. Safety of batch process. pp. 38-39 (1987).

|

| Number of Injuries |

2 |

| Physical Damage |

A measuring drum was damaged severely. |

| Multimedia Files |

Fig3.Chemical formula

|

| Field |

Chemicals and Plants

|

| Author |

ITAGAKI, Haruhiko (Japan National Institute of Occupational Safety and Health)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|

|