| Case Name |

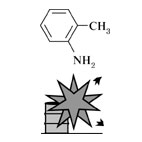

Explosion due to condensation from miss-charge of toluidine into a vessel of diketene |

| Pictograph |

|

| Date |

September 20, 1972 |

| Place |

Itabashi, Tokyo, Japan |

| Location |

Chemical factory |

| Overview |

An explosion accident happened due to miss-operation of a valve on starting a batch reaction at a synthetic plant for organic chemicals.

In the reactor in which dimethyl acetanilide was synthesized from diketene and o-toluidine, o-toluidine was added to the drop tank of toluene solution of diketene by a valve operation error.

Originally, the reaction required diluted cold diketene to be dropped into a cold toluene solution of toluidine, as this reaction generates much heat. The temperature rose sharply with a lot of heat being generated, and the accident occurred.

There was a mistake in the procedure and the operation at batch reaction start-up. |

| Incident |

As the procedure for reaction startup at a synthetic factory of an organic chemical was incorrect, an explosion occurred. To prepare dimethyl acetanilide, a condensation reaction of diketene and o-toluidine was carried out. As toluidine was put into a dropping tank for diketene diluted with toluene by mistake, a rapid exothermic reaction occurred and it exploded by the unusual reaction.

In the original procedure, a toluene solution of toluidine was prepared in the reactor, cooled, and agitated. The cold diketene diluted with toluene was dropped into the reactor and a reaction is caused. This procedure was selected because this reaction generates much heat. |

| Processing |

Manufacture |

| Individual Process |

Feed and charge |

| Process Flow |

Fig2.Unit process flow

|

| Chemical Reaction |

(Condensation) |

| Chemical Equation |

Fig3.Chemical reaction formula

|

| Substance |

Diketene, Fig4 |

| O-toluizine, Fig5 |

| Type of Accident |

Explosion, Environmental pollutions, health hazard |

| Sequence |

On September 20th, 1972. At a plant that was manufacturing dimethyl acetanilide, after putting toluene into a reactor, the shift changed.

About 16:00, the next shift operator put diketene diluted with toluene into the drop tank. Then, o-toluidine was put into the drop tank of diketene in which diketene had already been put.

Reaction gas spouted out from the outdoor vent pipe of the drop tank.

The operator sprayed water onto the drop tank for cooling, and closed the valve at the suction of the pump to stop charging toluidine.

The drop tank exploded soon after.

Nearby inhabitants complained about sore eyes caused by the diketene vapor. |

| Cause |

The operator mistook the injection tank of toluidine and made a valve operation error. As o-toluidine was put into the dropping tank of diketene, an extraordinarily rapid exothermic reaction occurred. |

| Response |

Water was sprayed with the hose from a water pipe for cooling.

An attempt to reduce the pressure by opening another valve, etc. |

| Countermeasures |

If the batch equipment is exclusively for this reaction, making equipment supply chemicals only to the correct original tank is a fundamental measure.

If it is multi-use equipment, checks and physical separation of the valve before work by two or more persons and education are required. |

| Knowledge Comment |

The potential danger of a batch chemical process has appeared. In a batch chemical process, work procedure and raw materials to be used often change with the product being manufactured. Therefore, it is necessary to study the work standard and the countermeasures in an emergency in detail beforehand. |

| Background |

It seems to be a simple human error. It is an old accident and details of the accident were not clear from the reports obtained.

However, it seems that the work procedure instruction sheet for not making a valve operation error, education, and prior recognition of the hazard of an exothermic reaction were insufficient.

It is presumed that indication measures were not taken, for example, color coding of the valve to make an operation error difficult.

There was a fundamental defect in the safety design and it seems that safety management was inadequate. |

| Reason for Adding to DB |

Example of explosion caused due to contamination from miss-operation of a valve on start-up of a batch reaction |

| Scenario |

| Primary Scenario

|

Organizational Problems, Inflexible Management Structure, Insufficient Education/Training, Carelessness, Insufficient Understanding, Insufficient Recognition of Risk, Condensation Reaction, Planning and Design, Poor Planning, Poor Design, Regular Operation, Nonobservance of Procedure, Bad Event, Chemical Phenomenon, Abnormal Reaction, Secondary Damage, External Damage, Explosion, Bodily Harm, Death, Bodily Harm, Injury, Bodily Harm, Sickness, 300 near-by inhibitants pained, Loss to Organization, Economic Loss, 1Working House Burnt Completely

|

|

| Sources |

Japan Assoc. of Fire Science and Engineering. Chemistry fire committee, D.35.2. The diketene. Case 247, examples of chemical fires (2), pp.126-127 (1974)

Masamitsu Tamura, Masahide Wakakura, Diketene explosion, Reaction danger - Accident examples and analysis - p.30 (1995)

|

| Number of Deaths |

1 |

| Number of Injuries |

1 |

| Physical Damage |

Serious damage to the workplace of one-story, slate roof, and steel frame structure. Almost all the facilities were destroyed by fire. |

| Consequences |

About 300 nearby inhabitants took refuge on their own judgment. The nearby inhabitants complained about sore eyes and throats due to the pungent smell of diketene. |

| Multimedia Files |

Fig4.Chemical formula

|

|

Fig5.Chemical formula

|

| Field |

Chemicals and Plants

|

| Author |

ITAGAKI, Haruhiko (Japan National Institute of Occupational Safety and Health)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|

|