| Case Name |

Explosion of a machine for melting and volume reduction of polystyrene foam |

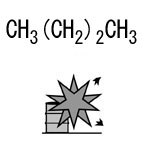

| Pictograph |

|

| Date |

June 14, 1997 |

| Place |

Shizuoka Prefecture, Japan |

| Location |

Plastic regeneration factory |

| Overview |

An explosion occurred during a trial run of a melting volume reduction machine for expanded polystyrene. Gases generated and accumulated in the machine. At garbage disposal equipment, safety countermeasures tend to be neglected, though accidents can occur because various chemicals are handled. Besides, the awareness of workers of safety is low compared with the case of a chemical plant. Therefore, it is important to point out risk factors in advance, install intrinsically safe equipment and provide education. |

| Incident |

An expanded polystyrene melting and volume reduction machine was being operated for the first time. An explosion occurred five or ten minutes after waste expanded polystyrene was charged. A worker was killed by a charge door blown off from the machine. |

| Processing |

Waste and disposal |

| Substance |

Butane, Fig2 |

| Polystyrene, Fig3 |

| Type of Accident |

Explosion |

| Sequence |

09:00 on June 14th, 1997. A volume reduction machine was installed.

10:00. Installation conditions were confirmed by the dealer, and power supply was turned on.

10:15. Warming up operation was carried out for 45 minutes.

11:00. The dealer provided explanation on handling.

13:30. Trial operation started with charging expanded polystyrene.

13:35. A worker fell in front of the machine. |

| Cause |

As gases such as butane and styrene are generated when waste expanded polystyrene is melted, ventilation is carried out five times a minute. However, the internal structure of the furnace caused retention of gases, and butane and styrene in the exhaust gas were ignited by static electricity sparks. |

| Countermeasures |

In melting treatment of waste plastic, the possibility of generation of flammable gas has to be known, education and training should be carried out, and safety countermeasures against a combustible gas-air mixture have to be taken. |

| Knowledge Comment |

Although chemicals are frequently handled at waste treatment facilities, a person in charge tends to lack chemical expertise. In such facilities, intrinsic safety is required more than in the case of chemical plants. |

| Background |

1. Workers lacked safety knowledge, and education and training had not been provided, although the generation of flammable gas was expected.

2. The static electricity countermeasures were not properly taken.

3. The upper part of the melting machine did not have an explosion door or a pressure releasing hole for an explosion. |

| Reason for Adding to DB |

Example of explosion caused due to common lack of safety knowledge and countermeasures at garbage disposal equipment |

| Scenario |

| Primary Scenario

|

Poor Value Perception, Poor Safety Awareness, Insufficient Safety Measure, Organizational Problems, Inflexible Management Structure, Insufficient Education/Training, Ignorance, Insufficient Knowledge, Insufficient Study, Planning and Design, Poor Planning, Poor Design, Bad Event, Thermo-Fluid Event, Stagnation, Secondary Damage, External Damage, Explosion, Bodily Harm, Death

|

|

| Sources |

Safety and Health Information Center of Japan Industrial Safety and Health Assoc., Labor accident case. No.100211. Explosion of expanded polystyrene as industrial waste when melted by fin heater. The Japan Industrial Safety and Health Assoc. home page.

Japan Industrial Safety and Health Assoc. Details of accident situation.

|

| Number of Deaths |

1 |

| Multimedia Files |

Fig2.Chemical formula

|

|

Fig3.Chemical formula

|

| Field |

Chemicals and Plants

|

| Author |

WAKAKURA, Masahide (Kanagawa Industrial Technology Research Institute)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|