| Case Name |

Fire caused due to electrostatic charge in the filtration process of a medicine intermediate |

| Pictograph |

|

| Date |

March 15, 1985 |

| Place |

Shin-nanyo, Yamaguchi, Japan |

| Location |

Chemical factory |

| Overview |

On manufacturing a pharmaceutical intermediate, a solid was filtrated from an n-hexane solution, and taken off from the filter. At that time, a fire occurred. Evaporation of n-hexane and electro-statically charged filter cloth were the causes of the fire. It seems to be a factor that the manufacturer did not know that the fluid component remains in the solid after filtration. |

| Incident |

A pharmaceutical intermediate obtained as a filter cake was transferred to a drier from a filter. N-hexane remained in the filter cake evaporated, and was ignited by a static electricity discharge. |

| Processing |

Manufacture |

| Individual Process |

Separation |

| Substance |

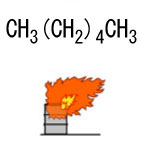

Hexane, Fig2 |

| Type of Accident |

Fire |

| Sequence |

1. The reaction of the medicine intermediate finished, and filtration with a filter finished.

2. Transfer of a filter cake started from the filter to the drier. Transfer was executed by gravity from the bottom of the filter to the drier via a polypropylene shooting device attached at the bottom of the filter. An operator hit the shooting device by his hand to prevent the device from clogging.

3. When transfer finished, the operator raked out the products remaining in the filter. At that time, a fire occurred suddenly in the shooting device. |

| Cause |

1. N-hexane remained at about 20% in the filter cake, which was the product. A combustible gas mixture was generated near the shooting device.

2. Static electricity was charged in the filter cloth when polyethylene filter cloth and a filter cloth presser were drawn from the glass-lined filter, and a static electricity discharge occurred at the metal part of the filter. |

| Response |

Fire-extinguishing activities by a private fire brigade. Public fire fighters turned out. |

| Countermeasures |

1. The concentration of N-hexane of a filter cake should be lowered when transfer is executed.

2. Electro-conductive material is used for the filter cloth.

3. The company carries out safety education for operators. |

| Knowledge Comment |

1. Static electricity is charged when the material is handled with a non-conductive device. However, this is often forgotten.

2. A solid after filtration (a filter cake) can not be 100% dry. A liquid remains at tens of percent. It is natural for a combustible gas mixture to be formed when a liquid is volatile. |

| Background |

1. The members of manufacturer had no interest in electrostatic charges. It seemed that they had no consciousness of charging of polypropylene which is non-conductive.

2. They did not take note of n-hexane vapor. As for a filter cake, a liquid component remains in the cake to some extent. If the liquid is volatile, it vaporizes and makes a gas-air mixture. It has an odor, which indicates the existence of combustibles. Consciousness of safety was reduced because there had not been an accident for a long time. |

| Reason for Adding to DB |

Example of fire caused due to electrostatic charge originating from the use of non-conducting cloth |

| Scenario |

| Primary Scenario

|

Poor Value Perception, Poor Safety Awareness, Poor Safety Measure, Organizational Problems, Poor Management, Poor Operation Management, Ignorance, Insufficient Knowledge, Insufficient Study, Planning and Design, Poor Planning, Poor Design, Regular Operation, Erroneous Operation, Operation as Usual, Bad Event, Thermo-Fluid Event, Static Electricity, Bad Event, Chemical Phenomenon, Evaporation, Secondary Damage, External Damage, Explosion, Loss to Organization, Economic Loss, Manetary Damage 4 million yen

|

|

| Sources |

Japan Industrial Safety and Health Assoc. Safety and health information center. Case of labor accident. No.631. Fire in pharmaceutical intermediate manufacturing process. The Japan Industrial Safety and Health Assoc. home page.

|

| Physical Damage |

Filter cloth, shooting devices, filters for air conditioning equipment, flexible hoses, and products, etc. |

| Financial Cost |

¥ 4 million. (by Itagaki material) |

| Multimedia Files |

Fig2.Chemical formula

|

| Field |

Chemicals and Plants

|

| Author |

KOBAYASHI, Mitsuo (Office K)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|

|