| Case Name |

Explosion and fire caused due to decomposition of an organic peroxide catalyst |

| Pictograph |

|

| Date |

October 1, 1993 |

| Place |

Yokkaichi, Mie, Japan |

| Location |

Chemical factory |

| Overview |

A special synthetic resin manufacturing plant was shut down, but a catalyst feed pump was not stopped, and continued circulation operation of a catalyst. Therefore, the temperature of the organic peroxide catalyst rose, and the catalyst exploded due to self-exothermic decomposition. An understanding of heat accumulation from circulation operation of the pump was lacking. |

| Incident |

There was an explosion during a temporary shutdown procedure at a plant that manufactured a special synthetic resin based on ethylene and propylene. An organic peroxide catalyst feed pump was not stopped during the plant shutdown, and circulation operation was continued. An explosion occurred at a catalyst preparation tank. |

| Processing |

Manufacture |

| Individual Process |

Feed and charge |

| Substance |

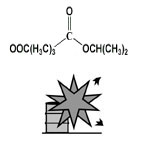

t-butyl peroxyisopropylcarbonate, Fig2 |

| Type of Accident |

Explosion, fire |

| Sequence |

At 19:15 on September 26th, 1993, a special synthetic resin manufacturing plant was shut down for a change of the grade. However, at the plant shutdown, a catalyst feed pump continued running to continue recirculation operation of the catalyst.

On October 1st, preparation work was conducted to restart the plant.

About 15:20, through the window of the control room, smoke was seen spouting from a vent pipe of a safety valve of a catalyst preparation tank. The safety valve of the catalyst preparation tank operated.

About 15:20, the catalyst pump was stopped hurriedly. However, with a sound of an explosion, black smoke rose, and a fire occurred. The plant was stopped immediately. |

| Cause |

The catalyst pump had been driven without stopping. As the circulating liquid absorbed the heat generated by pumping and frictional heat of the piping, etc, the temperature of the circulation liquid rose, and organic peroxide caused a decomposition reaction. |

| Response |

Water spraying by the company's fire fighters and the public fire brigade. |

| Countermeasures |

1. An interlock for a pump should be installed so that the pump can be always stopped during a plant shutdown.

2. Reeducation on organic peroxide must be executed.

3. The operation standard should be revised. |

| Knowledge Comment |

The efficiency of the pump was not 100%. The inefficient part is converted into heat. When the heat released from the system is smaller than the total of heat generated by pump and friction in the system, the pumping liquid temperature inevitably rises. When the circulation operation is done, a dangerous condition is caused. |

| Background |

The basic factor might be a lack of understanding of how the input energy of the pump is consumed. As pump efficiency is not 100%, part of the energy is converted into a temperature rise of the pumping liquid. Besides, during circulation operation, the pressure buildup energy of the pumping liquid is used for internal friction and friction between the pumping liquid and a pipe line. In other words, all the energy that enters the pump should be regarded as being converted into a temperature rise of the liquid. This is common sense in operating a pump.

A temperature rise is a reasonable consequence if the circulation operation of the pump is performed. It can be said that knowledge of the danger of the operation was insufficient, taking consideration into the characteristics of the catalyst together with pump operation. |

| Reason for Adding to DB |

Example of explosion caused due to a temperature rise from not stopping a pump on plant shut-down |

| Scenario |

| Primary Scenario

|

Poor Value Perception, Poor Safety Awareness, Inadequate Risk Recognition, Organizational Problems, Poor Management, Poor Operation Management, Ignorance, Insufficient Knowledge, Insufficient Study, Planning and Design, Poor Planning, Poor Tuenaround Shutdown Planning, Regular Operation, Erroneous Operation, No Service in Cooling Water, Bad Event, Thermo-Fluid Event, Friction Heat, Bad Event, Chemical Phenomenon, Abnormal Reaction, Secondary Damage, External Damage, Explosion/Fire, Loss to Organization, Economic Loss, Manetary Damage 15 million yen

|

|

| Sources |

Fire and Disaster Management Agency. Fire and explosion caused by the decomposition reaction of catalyst. Accident cases of dangerous materials. 1993. pp.284-287.

High Pressure Gas Safety Inst. of Japan. High-pressure gas protection overview. 1995 edition. pp.264-265(1995).

|

| Physical Damage |

Equipment for catalyst preparation and walls of a plant building with a steel structure and a slate roof partially burned. An adjacent plant partially burned. |

| Financial Cost |

¥ 15 million. (Fire and Disaster Management Agency) |

| Multimedia Files |

Fig2.Chemical formula

|

| Field |

Chemicals and Plants

|

| Author |

KOBAYASHI, Mitsuo (Office K)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|

|