| Case Name |

Explosion and fire of benzoyl peroxide (BPO) |

| Pictograph |

|

| Date |

May 26, 1990 |

| Place |

Itabashi, Tokyo, Japan |

| Location |

Chemical factory |

| Overview |

Highly purified benzoyl peroxide (BPO) exploded during the packaging process after methanol washing and methanol removal by evaporation. Ignition of residual methanol by electro-static sparks from a worker might have caused the fire and explosion. Although mass storage of BPO without a license led to expansion of the scale of the accident, it was not the direct cause. It can be said that a constitutional problem of the managers who passed over the contraventions of workers was an indirect cause of the accident. |

| Incident |

At a benzoyl peroxide (BPO) manufacturing plant, an explosion and fire occurred during packaging work of a high-concentration product. The entire factory was destroyed, and damage reached residential units in the neighborhood. |

| Processing |

Manufacture |

| Individual Process |

Filling and subdivision |

| Process Flow |

Fig2.Unit process flow

|

| Substance |

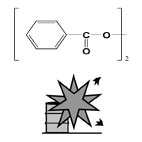

Benzoyl peroxide, Fig3 |

| Methanol, Fig4 |

| Type of Accident |

Explosion, fire, health hazard |

| Sequence |

08:30 on May 26th, 1990: Refuse, etc. of BPO products which were dried in an adjacent drying room was removed by manual operation, and the BPO was transferred to the packaging room in a truck.

09:30: After water was sprayed over the floor as an anti-electrostatic measure, the packaging work to pack powder BPO from a fiber drum (40 cm diameters, 70 cm heights) in vinyl bags with a plastic shovel started.

10:40: Ignition occurred, followed by an explosion. A small fire in the packaging room spread gradually. |

| Cause |

The packaging room that exploded first collapsed completely, and all four workers were killed. Post-accident investigation with experiments was conducted and the following was presumed. Methanol vapor from half-dried BPO made a combustible fuel-air mixture which was ignited by electrostatic sparks from a BPO packaging worker. This fire spread to BPO dust in the fiber drum and BPO itself, and there was an explosion. Moreover, the explosion caused a secondary explosion of BPO stored in adjacent buildings, and a fire and damage spread. |

| Countermeasures |

As it is a highly hazardous material, the working safety standard for handling BPO was revised, and safety education for workers was provided thoroughly.

As countermeasures against electrostatic sparks that are ignition sources, an explosion-proof structure was adopted. Against ignition of BPO itself, soft and electro-conductive equipment, tools, and a floor were adopted, |

| Knowledge Comment |

On handling of materials with already-known hazards, safety education and improvement in working safely standards are important. |

| Background |

What caused the fire and damage to spread was the hazardous properties of BPO and storage in large quantities.

If the estimation described in the "Cause", which shows that methanol vapor was ignited by electrostatic sparks from a worker, is correct, the most fundamental countermeasures such as fixing a standard for dryness or antistatic protection for workers were not taken. As there were some precedent accidents to this explosion, the essential problem was the attitude of the company, which ignored or underestimated the hazard of BPO. |

| Sequel |

Large amounts of benzoyl peroxide, which has very hazardous properties, had been stored in a food additive factory and product warehouses for years with no license by the company, and the managers knew that. This contravention was accused by the competent police, because it was a very serious contravention. Related laws and regulations must be obeyed. |

| Reason for Adding to DB |

Example of explosion caused due to two-step ignition from a solvent to organic peroxide |

| Scenario |

| Primary Scenario

|

Poor Value Perception, Poor Organizational Culture, Concealment Tendency of the Company, Organizational Problems, Inflexible Management Structure, Insufficient Education/Training, Carelessness, Insufficient Understanding, Insufficient Recognition of Risk, Planning and Design, Poor Planning, Poor Process Design, Regular Operation, Erroneous Operation, Insufficient Drying, Secondary Damage, External Damage, Fire/Explosion, Bodily Harm, Death, 8 person died, Bodily Harm, Injury, 18 person injured, Loss to Organization, Economic Loss, Direct Monetary Damage 150 million yen, Conpensation 700 million yen, Damage to Society, Social Systems Failure

|

|

| Sources |

Fire and Disaster Management Agency, Fire caused by explosion at chemical plant producing benzoyl peroxide, etc. Accident examples of dangerous materials. 1990, pp. 66-67.

Tokyo Fire Dep., Fire Prevention Div. research section, Outline of fire investigation of D chemical industry, No.1 factory fire caused by explosion. Modern fire fighting No.470, pp.95-101(2000).

|

| Number of Deaths |

9 |

| Number of Injuries |

17 |

| Physical Damage |

A packaging room collapsed almost completely. Total 902 square meters of seven factory buildings and one adjacent office building were destroyed by fire. 33 apartment buildings received minor damage such as broken windows, and 19 automobiles were damaged. |

| Financial Cost |

¥ 154 million. (Fire and Disaster Management Agency) |

| Economic Loss |

¥ 154 million (The private settlement was made between the company and bereaved families with compensation of about ¥ 7 hundred million in total on December, 27) |

| Consequences |

Residents in the vicinity had sore eyes caused by an irritating odor, and were evacuated temporarily. |

| Multimedia Files |

Fig3.Chemical formula

|

|

Fig4.Chemical formula

|

| Notes |

Discoloration of leaves of trees near the factory was found after the accident. After the discharge of organic peroxide, it reacts rapidly and does not seem to remain. Other persistent chemical substances do not seem to be generated. |

| Field |

Chemicals and Plants

|

| Author |

ARAI, Mitsuru (Environmental Science Center, The University of Tokyo)

YOSHINAGA, Jun (Graduate School of New Frontier Sciences, The University of Tokyo)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|

|