| Case Name |

Explosion and fire caused due to mixing of waste acids of different concentrations in a waste acid tank. |

| Pictograph |

|

| Date |

November 9, 1998 |

| Place |

Yoshitomi, Fukuoka, Japan |

| Location |

Chemical factory |

| Overview |

Production of methyl ethyl ketone peroxide (MEKPO) of a new grade started. Although the concentration of the waste acid was rather low compared with that of the old grade, it was run down into the tank of the old waste acid. Heat of dilution was generated by the mixing of waste acids, and it reached a high temperature. MEKPO in the new grade waste acid started self-heating decomposition at a high temperature, and exploded. In laboratories, cases of mixing hazards of wastes are reported in great numbers. |

| Incident |

A fire and explosion occurred in the night, after putting waste acid of methyl ethyl ketone peroxide (MEKPO) into a 2 cubic meter waste acid tank. |

| Processing |

Manufacture |

| Individual Process |

Waste water and waste oil treatment |

| Substance |

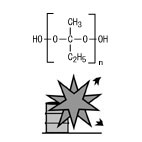

Methyl ethyl ketone peroxide, Fig2 |

| Sulfuric acid, Fig3 |

| Type of Accident |

Explosion, fire |

| Sequence |

Two batches of the new grade MEKPO were produced, and the waste acid of the new grade was put into the 2 cubic meter tank which contained waste acids of another grade manufactured last week. Part of the waste acid in the tank was put into a 10 cubic meter waste acid tank afterwards. A fire occurred after an explosion at 21:59 when workers were in the waiting room. |

| Cause |

Waste acid contaminated with MEKPO of a new grade, which had rather low concentration, was introduced into a 2 cubic meter waste acid tank with concentrated acid. Therefore, MEKPO in the new grade waste acid was rapidly decomposed by heat of dilution and caused ignition. |

| Response |

After the worker confirmed the fire, a fire alarm was activated and fire extinguishing was carried out with a fire engine and an outdoor fireplug. |

| Countermeasures |

Production of the new grade MEKPO was stopped. For other products using sulfuric acid, heating stability and hazards of mixing waste acid were evaluated, and safety of the facilities was improved. |

| Knowledge Comment |

Reactions caused due to mixing of wastes and/or waste water, and their resulting ignition and explosions tend to be overlooked, and it is necessary to take care in procedures to prevent accidents. |

| Background |

Lack of knowledge and ignoring of heat of dilution might have been problems. Probably, the procedure for waste acid management was kept same as the previous manner after the new product was manufactured, because the manager did not understand the effects of mixing of wastes. |

| Sequel |

Although in a simulation using actual waste acid there was no ignition, a rather high exothermic reaction was observed. |

| Reason for Adding to DB |

Example of explosion and fire caused due to heat of dilution |

| Scenario |

| Primary Scenario

|

Insufficient Analysis or Research, Insufficient Practice, Ignore the Actual Operation, Poor Value Perception, Poor Safety Awareness, Inadequate Risk Recognition, Ignorance, Insufficient Knowledge, Insufficient Study, Planning and Design, Poor Planning, Poor Process Design, Bad Event, Chemical Phenomenon, Abnormal Reaction, Secondary Damage, External Damage, Explosion/Fire

|

|

| Sources |

Fire and Disaster Management Agency, Waste acid FRP tank explosion and fire accidents in effluent treatment facility of the organic peroxide production, Accident cases of dangerous materials, 1998, pp.104-107.

|

| Physical Damage |

A waste acid tank completely collapsed. Adjacent effluent treatment facilities were destroyed by fire (a waste alkali tank and connection piping completely collapsed). The windows of an office 20 m from the tank was damaged by a blast. (Fire and Disaster Management Agency) The wall surface of the factory was damaged over about 100 square meters by a blast. (Yomiuri Shimbun). |

| Financial Cost |

¥ 3 million. (Fire and Disaster Management Agency) |

| Multimedia Files |

Fig2.Chemical formula

|

|

Fig3.Chemical formula

|

| Field |

Chemicals and Plants

|

| Author |

ARAI, Mitsuru (Environmental Science Center, The University of Tokyo)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|