| Case Name |

Dust explosion and fire during feeding bisphenol A to a dissolution drum |

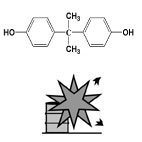

| Pictograph |

|

| Date |

November 5, 1990 |

| Place |

Ichihara, Chiba, Japan |

| Location |

Chemical factory |

| Overview |

Raw material bisphenol A was being charged from a flexible container to a polycarbonate plant. Due to improper operations deviating from the manual, a larger volume of air than thought flowed into the nitrogen-purged atmosphere inside the receiving hopper. A dust explosion and a fire occurred when the bisphenol A powder was put into the hopper. |

| Incident |

An explosion and a fire of bisphenol A occurred near the charge hopper of a bisphenol A dissolution drum at a polycarbonate plant. A subcontractor's worker was injured. |

| Processing |

Manufacture |

| Individual Process |

Feed and charge |

| Process Flow |

Fig2.Unit process flow

|

| Substance |

Bisphenol A, Fig3 |

| Type of Accident |

Explosion, fire |

| Sequence |

08:30 on November 5th, 1990. Subcontractor's workers started work based on the operation manual.

About 08:45. An explosion and a fire occurred. The plant was shut down immediately. A field emergency command unit was established; disaster prevention activities started.

08:50. Water spraying started.

08:55. Public fire brigade arrived at the site.

08:55. The injured worker was recovered and taken to hospital.

08:56. The fire was confirmed to have been extinguished. |

| Cause |

As usual, bisphenol A was charged from a flexible container to a hopper. Then, a dust explosion ignited by static electricity occurred near the feeding nozzle of the hopper. Flames spread inside and outside the hopper. Usually, the hopper was purged with nitrogen. However, it is considered that oxygen above the limit oxygen concentration was present due to air influx caused by the following improper operations.

- The block valve had been opened before the flexible container was set, though the operation procedure described in the manual was the block valve is to be opened after setting the flexible container.

- The lift position of the flexible container was about 30 cm higher than usual, and there was a gap between the container and the feeding nozzle.

A flexible container is a flexible bag mainly for transporting granular materials. A feeding nozzle at the head and a discharge nozzle at the bottom are to be bound with straps. Carrier capacity is from 500 kg to 1 ton per bag. |

| Response |

After the fire started the plant was shut down immediately. |

| Countermeasures |

The following are to be done to avoid an increase of oxygen concentration inside the hopper.

- Attempt to improve the manual and technical education for subcontractor's workers.

- Establishing nitrogen charging facilities at the feeding nozzle of the hopper.

- Permanently establishing an oxygen meter inside the hopper. |

| Knowledge Comment |

As combustible powder has the potential to cause a dust explosion, they must be treated with care. In this accident, a serious problem was that subcontractor's workers did not work strictly according to the manual. It also seems to be important to design plants in which a small failure does not directly cause an accident. For example, reinforcing the nitrogen-charging facilities and installing an oxygen meter. |

| Background |

The main cause of this accident was that a larger volume of air than thought flowed into a nitrogen atmosphere due to improper operations deviating from the manual.

Assuming that there was a nitrogen atmosphere, the worker might not have paid careful attention to the generation and the accumulation of static electricity. There seems to have been overconfidence about safety. |

| Incidental Discussion |

It is a misconception to regard the whole container as having a safe nitrogen atmosphere because nitrogen has been fed. There must be a flow if nitrogen is fed in and out somewhere. When a flow exists, the concentration cannot be homogeneous. |

| Reason for Adding to DB |

Example of explosion caused due to deviation from operation instructions |

| Scenario |

| Primary Scenario

|

Organizational Problems, Poor Management, Poor Operation Management, Poor Value Perception, Poor Organizational Culture, Left Subcontrators Work, Carelessness, Insufficient Understanding, Inadequate Risk Recognition, Regular Operation, Erroneous Operation, Manual Violation, Bad Event, Chemical Phenomenon, Heat Generation/Ignition, Secondary Damage, External Damage, Explosion/Fire, Bodily Harm, Injury, Loss to Organization, Economic Loss, Manetary Damage 10 million yen

|

|

| Sources |

Fire and Disaster Management Agency. Major accidents in 1990. Industry and protection. Vol.7. No.22. pp.9-11(1991).

High Pressure Gas Safety Inst. of Japan. Polycarbonate manufacturing plant. Bisphenol A dust explosion fire. Accident examples of Petroleum refinery and Petrochemical units. pp.196-199(1995).

|

| Number of Injuries |

1 |

| Physical Damage |

Damage to a square folded plate (an external wall) at the sixth floor of the building, window frames, windows, and doors. |

| Financial Cost |

¥ 10 million (Fire and Disaster Management Agency) |

| Multimedia Files |

Fig3.Chemical formula

|

| Field |

Chemicals and Plants

|

| Author |

DOBASHI, Ritsu (School of Engineering, The University of Tokyo)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|