| Case Name |

Explosion caused due to unexpected contaminant during neutralization treatment in a waste water tank |

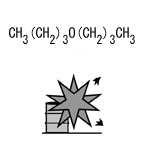

| Pictograph |

|

| Date |

September 16, 1999 |

| Place |

Ichikawa, Chiba, Japan |

| Location |

Chemical factory |

| Overview |

An explosion occurred in a waste liquid treatment tank of a factory preparing photosensitizers for semiconductors. The sodium hydroxide used for neutralization treatment contained a dibutyl ether liquid because it was a reused material and had been used for washing at another plant. Therefore, a combustible vapor was generated, and it was ignited by a static electricity spark. Sufficient consideration is necessary on using a reused material. |

| Incident |

An explosion occurred at a waste water tank of a factory manufacturing photosensitizers for semiconductors. Acid waste water of 2400 L (non-dangerous material) discharged from the water splitting part of a solvent (mainly benzene) was fed into the waste water tank of the manufacturing plant for a product named NAC-5, which is a secondary autoreactivity material. A 350 L of sodium hydroxide solution for neutralization treatment were fed into the same tank. Just at the moment the pump started to agitate the tank for internal fluid circulation, the valve of the piping for circulation was opened, the tank exploded, and there was a fire. One person received a slight injury. |

| Processing |

Manufacture |

| Individual Process |

Waste water and Waste oil treatment |

| Substance |

Dibutyl ether, Fig2 |

| Sodium hydroxide, Fig3 |

| Type of Accident |

Explosion, fire |

| Sequence |

About 12:22 on September 16th, 1999. An explosion occurred

12:43. The fire was extinguished. |

| Cause |

Sodium hydroxide used for neutralizing acid waste water was a liquid that had been used for washing a petroleum material (dibutyl ether, 100L (estimated)) at another plant. Therefore, the liquid (100L (estimated)) dibutyl ether had been contained. Part of the dibutyl ether evaporated after it was fed into the acid waste water tank, and a combustible gas-air mixture of dibutyl ether was generated in the vapor phase. The liquid in a pump and in the piping received an electrostatic charge due to flow friction when the pump started circulation agitation in order to promote neutralization. A discharge occurred when the residual liquid was fed into the tank vapor phase by opening the valve, and the combustible gas-air mixture was ignited and exploded. There is the possibility that the FRP tank and Teflon lining piping (they are insulating materials) also had an influence. |

| Response |

An emergency shutdown of the plant on manual. Initial fire fighting was performed with powder fire extinguishers. |

| Countermeasures |

1. Prevention of feeding of inflammable fluid contaminant into a waste water tank.

2. Earth of a tank made of FRP and Teflon lining piping.

3. Safety management on reuse of sodium hydroxide. |

| Knowledge Comment |

Reuse of chemicals for waste liquid treatment and little attention given to contamination caused the explosion and fire accident. Attention to contamination is necessary even for waste liquid treatment, because there is a serious hazard. |

| Background |

A reused sodium hydrate solution containing a flammable substance was used. The reason why it was used is the largest factor of the accident. Waste water and waste fluid have a tendency to contain other materials contacted or not separated completely while they are used in a process. Workers and managers did not understand the hazard of reused materials. An error in a fundamental recognition on process waste fluid is an important factor. |

| Reason for Adding to DB |

Example of explosion caused due to unexpected contamination in a waste water tank |

| Scenario |

| Primary Scenario

|

Poor Value Perception, Poor Safety Awareness, Inadequate Risk Recognition, Insufficient Analysis or Research, Insufficient Practice, Lack of Imagination, Planning and Design, Poor Planning, Poor Design, Bad Event, Chemical Phenomenon, Heat Generation/Ignition, Secondary Damage, External Damage, Explosion/Fire, Bodily Harm, Injury, Loss to Organization, Economic Loss, Manetary Damage 16 million yen

|

|

| Sources |

Fire and Disaster Management Agency. Explosion of the acid waste water tank of the neutralization treatment. Accident cases of dangerous materials. 1999. pp.62-64.

|

| Number of Injuries |

1 |

| Physical Damage |

One waste water tank was destroyed due to fire. A scrubber and a blower nearby were damaged by fire. Teflon lining piping, a pump, and a switch board for dryer were damaged by fire. |

| Financial Cost |

¥ 16 million (Fire and Disaster Management Agency) |

| Multimedia Files |

Fig2.Chemical formula

|

|

Fig3.Chemical formula

|

| Field |

Chemicals and Plants

|

| Author |

DOBASHI, Ritsu (School of Engineering, The University of Tokyo)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|