| Case Name |

Ignition of rubber remained in the reactor during cleaning at a polybutadiene manufacturing plant |

| Pictograph |

|

| Date |

July 6, 1997 |

| Place |

Ichihara, Chiba, Japan |

| Location |

Chemical factory |

| Overview |

A poly butadiene plant was shut down, a polymerization reactor was opened to the air, and accumulated rubber inside was removed. All of the rubber was not removed on the first day. It was decided to remove the remaining rubber on the next day. The polymerization reactor was left open. Residual butadiene rubber generated heat by air oxidization, and the rubber ignited spontaneously. It is necessary to simultaneously conduct oxygen-shortage prevention during work and prevention of oxidation by air. |

| Incident |

While a polybutadiene plant was shut down, a polymerization reactor was opened to the air, and it was cleaned. Residual butadiene rubber that had accumulated inside ignited and a fire occurred. |

| Processing |

Manufacture |

| Individual Process |

Maintenance |

| Substance |

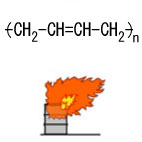

1,4-polybutadiene, Fig2 |

| 1,3-butadiene, Fig3 |

| Type of Accident |

Fire |

| Sequence |

The polymerization reactor at a polybutadiene plant was opened to the air, and removal work for residual rubber inside started. This work was done about once every two months.

About 17:00 on July 6th, 1997. As all of the rubber was not removed completely in the first day, it was decided to continue the removal work on the next day. The polymerization reactor was left open.

20:13. A fire occurred in the polymerization reactor. One fire engine and five fire fighters of a self fire fighting team turned out.

20:27. The public fire department was notified. Nine fire engines and 24 fire fighters turned out.

20:43. The fire was extinguished by spraying water. |

| Cause |

As accumulated residual polybutadiene generated heat by air oxidization, it ignited automatically.

In the past, accumulated rubber also caused ignition in a finishing process. |

| Response |

Water spraying with watering equipment.

Water spraying by self and public fire engines. |

| Countermeasures |

Before stopping a polymerization reactor, adding an oxidation inhibitor.

Sprinkling water on removing rubber in the polymerization reactor.

Reeducation by group training for accident prevention organization members. |

| Knowledge Comment |

During work done by hand in an open vessel, because ventilation must be performed to prevent an oxygen-shortage, air flows in. If there is a substance that generates heat by air oxidization, it will ignite spontaneously.

Although spontaneous ignition is not caused, as oxygen is consumed by the reaction, caution is needed about an oxygen shortage.

It should be considered that residual substances in a reactor are intermediate semi-finished goods of a reaction or impurities, not completed goods.

Spontaneous ignition takes place due to accumulation of heat. Therefore, if careful observation is performed, prevention is not so difficult. |

| Background |

The major cause was considered a mistake in safety management that overlooked the hazard of generating heat by air oxidization under dry conditions. If a reactor is opened to the atmosphere, naturally air flows in. They did not use the experience of past examples. |

| Incidental Discussion |

It is common sense in the butadiene field that high-concentration butadiene generates heat due to a polymerization reaction if there is oxygen even in a very small quantity. Moreover, it is also common sense that the polymerization substance generates heat in the presence of air. Many accidents related to butadiene have been reported. |

| Reason for Adding to DB |

Example of fire caused due to opening of a vessel containing polymerized substances with spontaneous ignition properties |

| Scenario |

| Primary Scenario

|

Poor Value Perception, Poor Safety Awareness, Inadequate Safety Measure, Insufficient Analysis or Research, Insufficient Prior Research, Study Not Grasping the Reaction Property, Ignorance, Insufficient Knowledge, Insufficient Study, Planning and Design, Poor Planning, Poor Overhaul Planning, Regular Movement, Careless Movement, No Showering for Safety, Bad Event, Chemical Phenomenon, Abnormal Reaction, Secondary Damage, External Damage, Fire

|

|

| Sources |

Fire and Disaster Management Agency, Fire in reactor that was shut down and opened to air. Accident cases of dangerous material. 1997, pp.290-291.

High Pressure Gas Safety Inst. of Japan, High-pressure gas protection overview. 1998 edition, pp.76-77 (1998).

The Res. Inst. of Industrial Safety material. (closed).

|

| Physical Damage |

Instrumentation and lighting facilities were destroyed by fire. |

| Financial Cost |

¥ 3 million. (Fire and Disaster Management Agency). |

| Multimedia Files |

Fig2.Chemical formula

|

|

Fig3.Chemical formula

|

| Field |

Chemicals and Plants

|

| Author |

ITAGAKI, Haruhiko (Japan National Institute of Occupational Safety and Health)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|

|