| Case Name |

Leakage of toluene caused due to incorrect disconnection of a coupling during draining of toluene for cleaning |

| Pictograph |

|

| Date |

July 13, 1998 |

| Place |

Wakayama prefecture, Japan |

| Location |

Chemical factory |

| Overview |

Leakage occurred because a coupling was released by mistake while toluene was being drained from a concentrator. The report says it was considered to be a simple mistake of an operator in the position of the coupling disconnection. However, the two couplings were located rather closely each other, with only a block valve between them, which could easily cause a mistake in operation. Also, the couplings had the same shape, so the mistake might not have been noticed. Safety measures should have been taken on the assumption that humans make mistakes. |

| Incident |

Leakage occurred during cleaning for an overhaul of a synthetic perfume manufacturing plant. When toluene was drained from a concentrator, a coupling was taken off at the upstream side instead of the downstream side of a block valve. Then about 200 L of toluene leaked. |

| Processing |

Manufacture |

| Individual Process |

Maintenance |

| Substance |

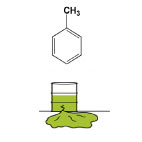

Toluene, Fig2 |

| Type of Accident |

Leakage |

| Sequence |

At a synthetic perfume manufacturing plant, facilities on the manufacturing line were being cleaned sequentially for a periodic overhaul. Toluene was being drawn off into a steel drum can from a concentrator after it was cleaned. As the drum became full, an operator tried to change it for a new one. When a hose for drain was taken off, the upper coupling of a block valve was disconnected, and about 200 L of toluene leaked out. |

| Cause |

The coupling at the upstream side of the block valve was taken off by mistake. The operator had to disconnect the coupling at the downstream side of the valve. |

| Response |

Recovery using an adsorption mat. Solid matter was recovered to a drum. |

| Countermeasures |

Safety education should be fully enforced.

Safety activities should be reviewed. It was an irregular hazardous operation even though it was a minor operation. So, the potential hazards should have been detected beforehand by safety activities at the site, such as KYK or TBM. |

| Knowledge Comment |

Humans make mistakes. |

| Background |

The case can be regarded as simple human error. However, the confusing coupling position and lack of measures against an operating error might be the basic causes. |

| Incidental Discussion |

The safety activities such as KYK (Training of hazard prediction) and TBM (tool box meeting) are supposed to be effective. However, were these activities carried out at the accident company? |

| Reason for Adding to DB |

Example of leakage caused due to insufficient consideration of an operator |

| Scenario |

| Primary Scenario

|

Poor Value Perception, Poor Safety Awareness, Inadequate Safety Measure, Carelessness, Insufficient Precaution, Carelessness of Operator, Planning and Design, Poor Planning, Poor Design, Regular Operation, Erroneous Operation, Mistake, Secondary Damage, External Damage, Leakage, Bodily Harm, Injury

|

|

| Sources |

Fire and Disaster Management Agency, Leakage while residual toluene (washings) was being drained from the concentrator, Accident cases dangerous materials. 1998, pp.1054-1056

Japan Association for Safety of Hazardous Materials, Cases of accidents in 100 dangerous material facilities. p.100, 1999

|

| Number of Deaths |

0 |

| Number of Injuries |

1 |

| Physical Damage |

Approx. 200 L of aToluene cleaning solution leaked onto the floor. |

| Financial Cost |

Less than ¥ 10,000 (Fire and Disaster Management Agency) |

| Multimedia Files |

Fig2.Chemical formula

|

| Field |

Chemicals and Plants

|

| Author |

WADA, Yuji (National Institute of Advanced Industrial Science and Technology)

YOSHINAGA, Jun (Graduate School of New Frontier Sciences, The University of Tokyo)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|