| Case Name |

Leakage of toxic substances at a chemical plant |

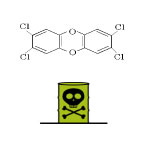

| Pictograph |

|

| Date |

July 10, 1976 |

| Place |

Seveso, Italy |

| Location |

Chemical factory |

| Overview |

In July, 1976, at a chemical plant in the suburbs of Milan, Italy, an accident occurred that caused diffusion of dioxin which is a deadly poison. After batch work, operators stopped the operation in an incorrect way, disregarding operating instructions. Therefore, the temperature rose, a large amount of dioxin was generated by a runaway reaction, a rupture disk operated, and contents including dioxin diffused into the atmosphere. The soil of 1800 hectares of land was contaminated, and 220000 persons were injured, suffering from sequelae. There was no correct knowledge among researchers and factory managers of a runaway reaction of the reactor, and the generation of dioxin from a runaway reaction. The damage spread because administrative authorities were not informed until the existence of high-density dioxin was reconfirmed.

Later, the disaster led to safety countermeasures named the Seveso Directive and the Basel Convention. In the history of chemical industry, this disaster is one of the largest accidents.

Though the trigger was disregard of the operation manual, it seemed to be an accident in which some design errors, incomplete research, secrecy within the company, etc. overlapped. |

| Incident |

At a plant which produced 2, 4, 5-trichlorophenol by a batch operation in the suburbs of Milan, Italy, batch operation was finished with a different method from that in the operation manual. Therefore, in a distillation vessel which was used also as a reactor, a runaway reaction occurred, and dioxin was generated in large quantities. As a result of the runaway reaction, a rupture disk operated, and reaction products including dioxin were discharged. Carried by the wind, the reaction products including dioxin spread over a wide area. When it fell to the earth in rain, there were a large scale of dioxin poisoning and people suffered from sequelae. Extensive soil pollution was caused. |

| Processing |

Manufacture |

| Individual Process |

Reaction |

| Process Flow |

Fig2.Unit process flow

|

| Substance |

2,3,7,8-tetrachlorodibenzo-p-dioxin (TCDD), Fig3 |

| 2,4,5-trichlorophenol, Fig4 |

| Type of Accident |

Leakage, environmental pollution, health hazard |

| Sequence |

16:00 on July 9th, 1976, a batch reaction started.

04:45 on July 10th, the reaction finished, distillation to ensure the reaction stopped, and heating was stopped.

05:00, an agitator of the reactor was stopped, and pressure was returned to atmospheric pressure. Operators left the plant.

12:37, a rupture disk of the reactor operated, and contents started diffusion. After the leakage, the factory manager gave a warning not to eat the products of kitchen gardens.

On July 15th, the existence of dioxin was confirmed in a laboratory of the parent company. However, the local government was not informed.

On July 20th, the existence of high-density dioxin was confirmed again in the laboratory of the parent company. The local government was informed at this time.

On July 24th, the local government informed inhabitants of the area of intense pollution and enforced evacuation. |

| Cause |

It was described in the operation manual that distillation should be stopped after recovery of 50% of an ethylene glycol solvent, water is injected, and cooled to the temperature of about 50-60 °C. However, the operators neglected these directions, and stopped the operation at 158 °C, with only 15% ethylene glycol recovery, without water injection. These events triggered the major disaster. The temperature rose, a runaway reaction occurred, dioxin was generated, and a rupture disk operated. As the rupture disk discharged material into the atmosphere, chemicals including dioxin were diffused throughout the atmosphere. In a laboratory, the existence of dioxin was confirmed five days later, but the local government was not informed immediately. After five more days, the existence of dioxin was confirmed again at the same laboratory. The local government was informed by the laboratory about the dioxin. Due to the delay in communication, the surrounding inhabitants were more exposed to dioxin, and the damage spread. |

| Response |

Enforced evacuation of inhabitants started after 14 days had passed. It was too late. |

| Countermeasures |

Removing all of the top soil. 1800 hectares were polluted and the direct countermeasure was soil dressing. Two large holes were dug; the polluted soil was buried in them; and, they were covered with concrete. There was no effective therapy for the victims, and 220000 persons suffered from sequelae.

Afterwards, there were the following countermeasures: Seveso Directives of EC was issued and Basel Convention of the United Nations was adopted. The former attempted to prevent major accidents and limit effects on human health the environment by the chemical industry. The latter was intended to prevent the transfer of pollutants across borders.

It seems to be important to emphasize the most fundamental matters in terms of facilities and operation. These are construction of the process, attention to materials, discharge of a rupture disk, prohibition of deviations from operating instructions, and establishment of a cooperative system among administrative authorities, regional inhabitants, and the company. |

| Knowledge Comment |

In the development process, engineering and written operation instructions should be prepared after all about the reactions in every reactor and process is understood. However, unknown aspects remain inevitably. During the engineering period and after start-up, the company had to continue to gather information and study the process, and then it should have reflected the results in the operation and the facilities of the plant.

The difficult problem is why stopping method was changed from the operation instructions. The instructions showed only the way without giving reasons. It might have led to disregard of the instructions. |

| Background |

1. The trigger seemed to be caused by a lowering of morale or insufficient education and training.

2. Until the disaster, it was said that a runaway reaction would occur above 230 °C. From the experiment after the disaster, the fact that an exothermic reaction starts even at 180°C became clear, and it was confirmed to be a runaway reaction.

3. It is said that the cause of a temperature rise from 158 °C to 180 °C was a hot spot. According to "Loss Prevention in the Process Industries," 300 °C steam was supplied during the stopping operation. In addition, the agitator was stopped. It was natural for a hot spot to be formed near the vessel wall. There is a description that 190 °C superheated steam was used, because a large temperature rise was not wanted. According to "Loss Prevention," the superheated steam came from turbine exhaust at a low load, so it is natural that the temperature would rise and reach 300 °C at stopping. The exhaust temperature of a steam turbine fluctuated with a load.

4. Prior to this accident, there were five similar accidents. The process the parent company selected was a method using ethylene glycol as a solvent, as well as the four preceding accidents. However, the same kind of accident occurred at a plant using ethylene glycol in 1968.

Moreover, although in this reaction, a maximum of about 10 ppm TCDD had been produced even in normal operation, the possibility in which the generation of TCDD was accelerated overlooks the fact. Besides, a runaway reaction was not considered.

5. Therefore, confirmation of the generation of a large quantity of dioxin in a runaway reaction and TCDD diffusion was delayed.

Extra time was spent because the report to the local government was also made after the reconfirmation.

6. As the discharge of the rupture disk was made into the atmosphere, it was useful for protecting the facility, but it caused dioxin diffusion.

There seems to have been a large design error. |

| Sequel |

Seveso Directives and Basel Convention |

| Incidental Discussion |

There were no direct fatalities. The abortion rate of pregnant women from April to June in the following year was abnormally high at 34%. Was this not murder?

According to Doctor Uehara's "the cause of the Seveso accident", 190 °C overheated steam was used as a heat medium for distillation to prevent the process temperature rising above 180 °C. According to "Loss Prevention", 300 °C steam was supplied during the accident due to a low load of the steam turbine. It is assumed that a mistake in the design of the utilities is a cause, if both of them are right. |

| Reason for Adding to DB |

The worst environmental pollution caused due to chemical substances. |

| Scenario |

| Primary Scenario

|

Organizational Problems, Poor Management, Slackness of Management, Poor Value Perception, Poor Safety Awareness, Insufficient Safety Measure, Insufficient Analysis or Research, Insufficient Prior Research, Insuficient Reaction Study, Planning and Design, Poor Planning, Mal Position of Rapture Disk Outlet, Regular Operation, Nonobservance of Procedure, Stopped as Temperature High, Bad Event, Chemical Phenomenon, Runaway Reaction, Secondary Damage, Damage to Environment, Environmental Pollution, Bodily Harm, Sickness, 220 thousand person sickness, Damage to Society, Social Systems Failure, Social Function Loss, Foeced Refuge, Loss to Organization, Social Loss, Loss to Organization, Social Loss, Loss to Organization, Economic Loss

|

|

| Sources |

Ikuo Fukuyama, After the Seveso accident. Prevention time signal. No.176. pp.19-25(1994)

Ikuo Fukuyama. Dioxin explosion and leakage accident in Seveso Italy. Important industrial accidents of the world. pp.40-43, 84-85 (1993)

Ikuo Fukuyama. Accident at Seveso. SE series. Study on accident. pp.10-13 (1987)

Yoichi Uehara, Terushige Ogawa. Fire prevention and explosion-proof control technology handbook. pp.8-11 (1998)

Yoichi Uehara. Cause of Seveso accident. Safety engineering. No.141. pp.340-345 (1987).

Environmental Public injuries and sanitation. Chemical industries of the world. pp.55-58 (1976)

Frank P.Lees. Loss Prevention in the Process Industries (2nd Edition) Appendix 3. Seveso (1996)

|

| Number of Injuries |

220000 |

| Financial Cost |

$48 - 50 million. About 140 hundred million yen. (Estimation by Italian authorities) |

| Consequences |

Forced evacuation of inhabitants of the polluted area by the state government. Plants and soil in the polluted area of 1807 hectares were also contaminated. Fig5. |

| Multimedia Files |

Fig3.Chemical formula

|

|

Fig4.Chemical formula

|

|

Fig5.Damage range figure

|

| Field |

Chemicals and Plants

|

| Author |

KOBAYASHI, Mitsuo (Office K)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|

|