| Case Name |

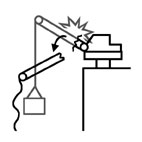

The tower crawler crane ( 150 tons ) fell while unloading. |

| Pictograph |

|

| Date |

June 1, 1998 |

| Place |

Otaru City, Hokkaido. |

| Location |

At the total gymnasium construction site |

| Overview |

* The ast boom of the tower crane fell from its root while unloading the temporary work material ( the column stage about 30 kilograms ).

* The fallen tower boom and jib fell into the construction site of another JV company.

* Two workers ( the riggers ), who had worked at the neighboring construction area, touched the wire stocked in its machine and got injured. |

| Sequence |

The boom and the jib spined back and came down to the ground ,and fell while unloading by using the tower crawler crane at the total gymnasium construction site in Hokkaido Otaru City at about 13:50 on 6/1 in 1998. |

| Cause |

* Taking over the work to the replaced operator was insufficient.

* The experience shortage of the operator who caused the accident. ( Though he had much experience of rough terrain crane etc., his duration of operating tower crawler cranes was short. )

* The mast was too wound up by the misoperation of the operator.

* Since the unusual coma was inserted in the back-stay, the crane was longer than the designed dimension and the load was taken earlier than the extreme moment limiter.

* Since the extreme moment limiter had been installed at the root of the mast boom, the rotation displacement was small and it was difficult to adjust it.

* Because the operator wound up the tower boom again on condition that the tower back-stop spring was adherent, the back-stop failed and fell down backward. And the spacer for the length adjustment of the back-stop spring was not standard. |

| Countermeasures |

* They should do luffing ( standing the mast ) at slow-speed and forbid the compound operations absolutely.

* They should have the operators and the replaced workers, who have small experience, get on the cranes after the sufficient practice education is done about the operating methods and safety equipment, etc..

* They should confirm that there is no abnormality by having workers report inspection results of the safety equipment in the assembly and opening inspection.

* They should have workers report about the important adjustments and the exchanging parts, etc., and should examine and confirm whether there are problems or not after discussing with the manufacturer.

* When a new operator enters working sites, they should confirm his qualification evidence, his safety and health education completion evidence and his operating experience for his machine. |

| Knowledge Comment |

* Don't turn off safety equipment! Prevent it from being turned off!

* The parts replacement is the safety replacement.

* Bases are the safest. |

| Background |

* Inspection shortage of the safety equipment ( The inspection items are difficult and too many )

* The overconfidence for the safety equipment ( The overconfidence is that computers are almighty )

* The habituation of the safety equipment release action ( Both construction sites and operators don't rely on the size of the models )

* Knowledge shortage for the safety equipment ( function, handling, inspection, etc. )

* The difficult safety equipment

* The increase in using inclined towers at construction sites ( Working on the narrow spot )

* The transition of safety equipments ( Each company uses very different terminology and equipments ) |

| Sequel |

(1) "The Committee examining the operating ability improvement of the transportable crane" was installed to the (Corp.) Japan Crane Society, and its members examined the prevention of accidents of tower cranes. Then, they made the educational text and video.

(2)"Crawler Crane Subcommittee" of (Corp.) Japan Construction Equipment Industry Association, which the manufacturers belong to, examined the improvement and the integration of the safety equipment of tower crawler cranes.

* The drastic improvement was carried out about the model sold after January, 2001. For example, various safety equipment have been made doble safety equipment etc.. |

| Account of Concerned Parties |

( The testimony of the operator )

After he had operated the boom at 85° angle and the jib angle from 65° to the drop side, his seat made a cracking sound and the boom slightly leaned forward and began to spin.

As this time was the momentary event taking about 2 seconds, they could not respond at all. |

| Reason for Adding to DB |

Because huge accidents are apt to increase and the material and human damage is large. |

| Scenario |

| Primary Scenario

|

Ignorance, Insufficient Knowledge, Regular Operation, Erroneous Operation, Regular Operation, Erroneous Operation, Failure, Deformation, Failure, Large-Scale Damage, Bodily Harm, Injury

|

|

| Sources |

The example for the safety education of the tower crawler crane operater.

|

| Number of Injuries |

2 |

| Physical Damage |

The boom |

| Financial Cost |

About 50 million yen. |

| Consequences |

If a disaster accompany human factor, it becomes a target of media and a social problem. |

| Field |

Civil Engineering

|

| Author |

OGISHIMA, Naoshi (Japan Crane Construction Constructors Association)

KUNISHIMA, Masahiko (The University of Tokyo)

|