| Case Name |

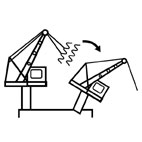

The tower crawler crane ( 150 tons ) collapsed while unloading. |

| Pictograph |

|

| Date |

September 2, 1998 |

| Place |

Tokushima City, Tokushima Prefecture. |

| Location |

The construction site of thermal power plant . |

| Overview |

When hanging the reinforced steel ( 300 - 500 kilogram ), the tower boom overturned at the machine rear. And the other tower crawler crane ( 150 tons ), which had been working behind it, was involved and also overturned. |

| Sequence |

* On that day, a worker had been discharging the load of about 300 - 500 kilogram since the morning and he did the work about 50 times.

* He cut the ground limits at a tower boom angle of about 87° , jib angle of 45° , and he operated the jib hoist motion lever and tower hoist motion lever, and next he operated the clockwise turning lever. Then, when he raised the tower boom at 89.4° , there was a strange noise and the left back-stop came off, and the tower boom greatly shook. Then, the tower and jib hoist motion levers were neutrally returned, but the tower collapsed.

* The counter-clockwise turning was carried out in order to avoid the rear crane when the crane collapsed.

* Tower boom worked usually from 87° within 90° . He generally keeps the tower hoist motion lever turning on since the automatic shut-down device works at 90° as concerned the tower , and he operated returning the lever after tower hoist motion had been stopped by the safety equipment.

* Rotational frequency of the engine was not idling (700rpm) but about 1000rpm. |

| Cause |

It is shown that they are the 1625mm, when the central distance between tops and bottom of spreader sheave for the tower corrugation was measured, and that that this dimension too be clearly wound occurs. |

| Countermeasures |

* The elimination of the overwind prevention devices release factor : Making the switch a key style, detaching and keeping its key in operating,and preventing release actions and occuring of easy misses.

* The improvement in the reliability of the extreme shut-down device : The extreme limit switch should be established about back-stop.

* The addition of the safety education : The prevention of overconfidence of safety equipments ( prohibition of the stopping the operation by depending on a safety equipment ). |

| Knowledge Comment |

Don't turn off a safety equipment! Don't keep it not been turned off! |

| Sequel |

Its machine verification result

* Though actuation confirmation of the safety equipments about preventing too rolling the tower after the accident, they all normally operated, and the abnormalities were not found.

* The angle sensor for preventing too rolling, limit switch, and solenoid valve were not abnormal, and all the shutdown systems functioned.

(a). It was confirmed that there was no rearrangement abnormality in the other its machine about installing an angle sensor and a limit switch from the collapse crane in the field, and it is considered that it was functioned just before the accident.

(b). It can be said that the indentation of the roller in the switch side had remained in the striker for the limit switch and that there were not miss swing of the striker. |

| Account of Concerned Parties |

( testimony of the operator ) The safety equipment functioned just before the accident on that day. |

| Scenario |

| Primary Scenario

|

Poor Value Perception, Poor Safety Awareness, Regular Operation, Erroneous Operation, Regular Operation, Erroneous Operation, Failure, Large-Scale Damage, Bodily Harm, Injury

|

|

| Physical Damage |

The boom |

| Financial Cost |

One hundred million yen. |

| Field |

Civil Engineering

|

| Author |

OGISHIMA, Naoshi (Japan Crane Construction Constructors Association)

KUNISHIMA, Masahiko (The University of Tokyo)

|

|