| Case Name |

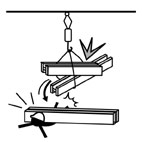

The wide-flange beam steel was entangled in the clamp, and it fell, and the worker under it suffered damage. |

| Pictograph |

|

| Date |

February 11, 1997 |

| Place |

Osaka prefecture. |

| Location |

The water purifing plant construction work field. |

| Overview |

It arose in the demolition work of the temporary pier used for water purifing plant construction work. The wide-flange beam steel was entangled and fell, then two workers under it sufferred and died , which happened during the loading work of the wide-flange beam steel once used for temporal bridge and was dismantled. |

| Incident |

The wide-flange beam steel loaded to the trailer was entangled in the clamp, and it fell, and two workers died under it. |

| Sequence |

For the removal work of the temporary pier used for this construction, the 60 sheet lining board was removed using the transportable crane, and temporarily they were put on the vacant land. Afterwards, they loaded them onto the trailer. After loading the lining board, they load the wide-flange beam steel directly onto the trailer picked out from the temporary bridge. When they rolled up the hook after loading the fourth beam steel, the clamp fixed on the edge of the hook was entangled to the beam steel, and the beam steel floated up. 2 workers working on the trailer jumped off ,but immediately after that, the beam steel fell and the workers died under it. |

| Cause |

Generally, the clamp called "one touch style" for lifting the wide-flange beam steel is on a mechanism demonstrated as a holding force is from the load in the lift set in the clamp opening. Since the operator of the crane and the chief was in the dead angle because of the floating up of the beam steel , so they could not notice the circumstance. |

| Response |

The recognition of danger and slinging work method of this clamp were informed to everybody thoroughly. |

| Countermeasures |

Instrument improvement and the decision of the slinging work method have to be informed. |

| Knowledge Comment |

The danger of machine instrument of high convenience must be grasped, and the work method must be examined beforehand. |

| Background |

The danger of using the clamp with the high convenience had not been recognized. Work was carried out in the dead angle of operator and work director while the heavy goods were being loaded. One of the victim had not participated in the previous arrangement before the works. |

| Reason for Adding to DB |

Even a highly convenient tool , it turns to be a cause of disaster due to the misuse. |

| Scenario |

| Primary Scenario

|

Poor Value Perception, Poor Safety Awareness, Ignorance, Insufficient Knowledge, Organizational Problems, Poor Management, Carelessness, Insufficient Understanding, Carelessness, Insufficient Precaution, Planning and Design, Poor Planning, Production, Hardware Production, Non-Regular Operation, Emergency Operation, Non-Regular Movement, Movement During Transition, Bodily Harm, Death, Possible Damage, Potential Hazard, Loss to Organization, Economic Loss, Loss to Organization, Social Loss

|

|

| Sources |

http://www.jaish.gr.jp/

|

| Number of Deaths |

2 |

| Number of Injuries |

0 |

| Physical Damage |

It is unknown that damage of the clamp and fallen wide-flange beam steel. |

| Field |

Civil Engineering

|

| Author |

HANAYASU, Shigeo (National Institute of Industrial Safety)

|

|