| Case Name |

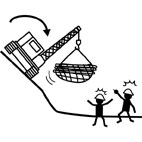

A crawler crane lifted heavier load than its set loading in a slope and fell. |

| Pictograph |

|

| Location |

A loading site of disassembly member of a platform used for shoring. |

| Overview |

Attachments were fitted at one time to 3 H-steels which was produced when dismantling a platform, and the driver left driver's seat from small transportable crane whose wire was stretched and other driver started lifting 3 H-steels as it was. When turning in the valley side, the transportable crane fell, and since the road shoulder collapsed, the victim was crushed to death under the crane. |

| Incident |

In the slope, the small transportable crane that lifted heavier load than its set loading rotated and fell, and the operator was crushed to death under the crane.

Still, though this operator was a qualified person, he was engaged in the work of transporting earth and sand in the truck. But, he suffered damage, because he alone decided to drive the small transportable crane, without the indication from the person in charge. |

| Sequence |

The disaster arose in removal work of the steel platform member used for shoring for landslide prevention.

At around 8:30 in the day, a site manager of the original contractor, a worker of the first subcontract, and a worker of the secondary subcontract gathered in the site, and the site manager gave the instruction about the work of carrying out by the truck steel plate and 15 H-steels which was produced when dismantling the platform.

The small transportable crane used for the work was a crawler crane of lift load 4.9t with the hydraulic rubber shoe (outside edge dimension of the shoe of both sides was 2.3m long, and its structure couldn't wide the shoe), and it had over-load cutout device and overwind prevention devices.

From around 9:30, the work was started, and the small transportable crane was placed in the slope below the place where the steel member to carry out was located, in addition, the truck which belonged to a leasing company was placed below the crane, and the work was carried out by loading the steel product to the truck.

The company which the victim belonged to played a key role in the loading work to the truck, and under the supervision

of the person in charge, the colleague, who had finished the sling skill classes, did the sling work and the worker of

secondary subcontract, who had finished the small transportable crane operation skill classes, drove the small

transportable crane. In respect of the sling, and to begin with, 10 H-steels were loaded to the load-carrying platform

of the truck, and the truck started to go outside.

Afterwards, since the work was late, in order to efficiently carry out the work, the colleague fitted attachments to 3

H-steels ( about 16.68t ) at one time, and he rolled up the hook of the crane and stopped the crane with its wire rope

stretched. At that time, in the sling, the length of the jib was 7m, the angle for the slope was 35 degrees, and he

thought that its set loading was about 1.2t, because operating radius was nearly 5m allowing for the slope.

Meanwhile, the crane operator thought that the weight of the load was 1.5t, and thought that in hanging the H-steels

he had to bring the crane close to the H-steel.

Then, though the second truck which transported steel product had climbed the slope in reverse, it slipped and stopped,

since it had got wet in the rain. The person in charge, sling person, and crane operator who noticed this left the crane

with its wire rope stretched, gathered in the truck, and observed that state.

At this time, the victim who was engaged in the work of carrying earth and sand by the truck stopped in this place.

The person in charge played a key role in consulting of workers and they reached the conclusion that the reason

that the truck could not climb the slope by slipping was lightness of the car body, that if things were loaded in the

platform, the car body would become heavy, and that it could not slip and would be able to climb the slope.

Then, the victim who had had completion evidence of small transportable crane operation skill classes and slinging

skill classes went for the small transportable crane, not waiting for the indication from the person in charge.

The victim who sat in driver's seat lifted 3 H-steels which had been slung and became the condition of immediately

lifting. When turning in the valley side, the transportable crane overturned.

Since the road shoulder collapsed because of the impact, it fell. It spun around in an almost circle, and it hit a tree

in middle point of the slope to stop.

Then, since the victim drove the crane without the door of its driver's seat close, he was thrown to the outside

from the its driver's seat, and was crushed to death under the crane. |

| Cause |

1. Lifting a heavier load than the set loading of the small transportable crane, it rotated.

2. When the attachment was fitted to 3 H-steels, both the crane driver and the sling worker knew that the load was heavier than its set loading, if the angle of the jib was not changed. But the right way of the work was not examined immediately, and measurements of the modification were not carried out.

3. The small transportable crane driver left the driver's seat with its wire rope stretched, and the other operator selfishly resumed the operation from this condition and rotated it.

4. The site manager left the site, while he gave the unclear instruction ( arrangements of the workers, sharing of the work, nominations of the signal person, etc. were not carried out ).

5. The education on danger in handling heavy goods in narrow place and on the countermeasure had not been made to the workers.

6. The over-load cutout device which had operated till the previous day did not operate at that time. |

| Countermeasures |

1. Work planning which incorporated using equipment, schedules of the work and procedures, staffing, etc. is made.

2. The work planning is communicated thoroughly to the contractor concerned and the worker concerned.

3. The crane operator and slinging worker are always made to learn so they can judge correctly the mass of lifting load, in order not to lift a heavier load than its set loading.

4. After determining the fixed signal, the transportable crane is driven.

5. A driver doesn't leave driver's seat with the load lifted. In the case that driver leaves the driver's seat, he stops the engine, and leaves, keeping the key himself.

6. Over-load cutout devices, etc. are checked before the work starts ( the opening inspection ). When the driver changes halfway, the former driver transmits the inspection result to the next, and the next driver personally checks again at the same time.

7. The safety education for the crane use is carried out for the worker concerned. |

| Knowledge Comment |

1. When a worker takes over an other's work halfway, they communicate elaborately about the matter of the work.

2. Jumping to conclusion is an origin of an accident.

3. Lifting heavier load than its set loading is an origin of an accident. |

| Background |

The worker intended to end the work early, because it was the final work in this year, and he was upset. |

| Scenario |

| Primary Scenario

|

Ignorance, Insufficient Knowledge, Ignorance of Procedure, Disregard of Procedure, Misjudgment, Misunderstanding, Organizational Problems, Poor Management, Usage, Operation/Use, Non-Regular Operation, Change in Operation, Regular Movement, Dangerous Movement, Failure, Large-Scale Damage, Bodily Harm, Death, Loss to Organization, Social Loss

|

|

| Number of Deaths |

1 |

| Physical Damage |

The small transportable crane. |

| Field |

Civil Engineering

|

| Author |

IKAI, Seiji (ICHITEC CORPORATION)

BABA, Kanji (ICHITEC CORPORATION)

|

|