| Case Name |

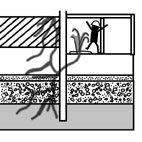

The water flowed from the joint of the wall, and the earth's surface subsided and private houses were damaged. |

| Pictograph |

|

| Date |

April 3, 1992 |

| Place |

Ebiko, Fukushima Ward, Osaka City |

| Location |

"Noda Hanshin Station of Katafuku link line (tentative name)" construction site in Osaka City |

| Overview |

At Noda Hanshin Station of Katafuku link line (tentative name) construction site in Osaka City, while the earthwork was carried out, with surrounded by an underground continuous wall and with supported by support timber, the water flowed from the joint of the wall, and sand and soil flowed into the excavation pit with water. The earth's surface subsided as a result, and the roadside houses were damaged. |

| Incident |

At about 13:40 on third April 1992, at Noda Hanshin Station of Katafuku link line (tentative name) construction site in Osaka City, the gravel flowed into the excavation pit along with the water of about 20000 cubic meters of water, and the earth's surface subsided, and the 34 roadside houses were damaged. It is considered that the water of 9 cubic meters of water at most flooded for 1 minute. |

| Sequence |

* The underground continuous wall was constructed by the muddy water solidification method, and the wall was 80m in length, 38m in depth and 70cm thick.. The wall was constructed with each element which was a construction unit, and a wall consisted of all if the element. After digging to 38m depth with using bentonite muddy water as a stabilizer for the prevention of the collapse of the porous wall and substituting solidification muddy water for the stabilizer, H-shaped steel structure was built up to 31m depth at intervals of 48cm. However, at the element where water flowed, since the noisy work was carried out in day time intensively out of regard for the roadside houses, H-shaped steel had been installed before substituting solidification muddy water for the stabilizer.

* The last floor of excavation was located at 24.1m depth from the earth's surface. On the day of the incident, excavation was finished up to 16.6m depth from the earth's surface, and then the whole area of excavation was divided into 4 blocks in order to prevent the swelling phenomenon. The excavation of the third block reached 21.4m depth, and that of the adjoining second block was 16.6m in depth. In the boundary of each block, the steel sheet pile was installed as a partition.

* At first, the water effluence was found as a spring water of blackish sludge. As an emergency measure, the countermeasure against water effluence such as filling back by the gravel was taken. However, it was not effective, and the quantity of water gradually increased, and after about 40 minutes, the earth's surface subsided, and 34 roadside houses were damaged. |

| Cause |

* The lower part of the alluvium silt layer under the last floor and the alluvium sand layer below was artesian aquifer including the sand with high fluidity.

* The difference might occur at the deformation volume of the wall because the boundary of the division matched the boundary of the element of solidification of muddy water, and the difference existed in excavation depth.

* As a problem of the construction of the element where water flowed,

1. There was less time for dealing with mud lime cake (a film of mud on excavation surface) and slime (lumps of the soil generated under excavation) at this element than other elements.

2. Several hours had passed after the treatment of the mud lime cake, so the new mud lime cake adhered easily to the H-shaped steel structure.

3. A slippage had been generated between the excavation width at the water effluence point and the road, and it was difficult to remove the mud lime cake. |

| Response |

As a result of grouting chemicals, and putting freshly mixed concrete to the borehole behind the solidification wall, the water stopped in the evening of the fifth April, two days after the water effluence appeared. |

| Countermeasures |

* The problem of the abnormal water effluence concerns design and construction. Therefore, the water effluence can be prevented by considering both construction and design.

* They must be careful about the suppressed water. Though the H-shaped steel structure was used as core material of the solidification wall of muddy water, it can be considered that the steel pile should be used if the water flow is intended to be stopped completely.

* Another method is to lower the ground-water level by the water-pumping method, in case that there is no danger of ground subsidence and the problem of the treatment of pumped water is solved. |

| Knowledge Comment |

* The problem of the abnormal water effluence concerns design and construction.

* The effective control by measurement.

* Collection of information about similar construction. |

| Sequel |

The fact of the accident which occurred 17 years ago has sufficiently been recognized. Though the construction method was different, it had been said that the construction of the joint part was an important point of the underground continuous wall from the beginning, and the important matter was also included in the added specification. |

| Reason for Adding to DB |

For preventing the same kind of construction disaster from coming about. |

| Scenario |

| Primary Scenario

|

Unknown Cause, Occurrence of Abnormal Phenomenon, Poor Response to Change in Environment, Change in Environment, Insufficient Analysis or Research, Insufficient Prior Research, Non-Regular Action, Change, Failure, Deformation, Failure, Large-Scale Damage

|

|

| Sources |

Measures for preventing a recurrence learning from 70 examples of grave accident - construction accident - , Nikkei Construction

|

| Number of Deaths |

0 |

| Number of Injuries |

0 |

| Physical Damage |

34 private houses |

| Financial Cost |

unknown |

| Economic Loss |

unknown |

| Consequences |

Construction disasters might cause social distrust of management responsibility of original contractors, and furthermore, it might increase anxiety and distrust of danger at construction site, which the neighboring residents have. |

| Field |

Civil Engineering

|

| Author |

TANAKA, Nobuyuki (Japan Engineering Consultants Co., Ltd.)

|

|