|

01. |

Poor Value Perception |

|

02. |

Poor Safety Awareness |

|

03. |

Insufficient Safety Measure |

|

04. |

Organizational Problems |

|

05. |

Poor Management |

|

06. |

Inadequate Operation Management |

|

07. |

Carelessness |

|

08. |

Insufficient Precaution |

|

09. |

Carelessness of Operator |

|

10. |

Planning and Design |

|

11. |

Poor Planning |

|

12. |

Poor Design |

|

13. |

Malicious Act |

|

14. |

Rule Violation |

|

15. |

Safety Rule Violation |

|

16. |

Bad Event |

|

17. |

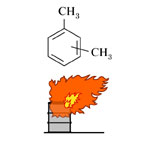

Chemical Phenomenon |

|

18. |

Evaporation |

|

19. |

Secondary Damage |

|

20. |

External Damage |

|

21. |

Fire |

|

22. |

Bodily Harm |

|

23. |

Injury |

|

24. |

I person injured |

|

|

|

Fire of ethylene oxide adducts at a manufacturing plant not in operation

|

|

Knowledge Comment: |

|

A tank level observation is needed not only detection by level instrument but also by estimation on computer and/or manpower. |

|

|

|

|