|

01. |

Poor Value Perception |

|

02. |

Poor Safety Awareness |

|

03. |

Inadequate Risk Recognition |

|

04. |

Organizational Problems |

|

05. |

Inflexible Management Structure |

|

06. |

Insufficient Education/Training |

|

07. |

Carelessness |

|

08. |

Insufficient Precaution |

|

09. |

Carelessness of operators |

|

10. |

Planning and Design |

|

11. |

Poor Planning |

|

12. |

Poor Design |

|

13. |

Regular Operation |

|

14. |

Nonobservance of Procedure |

|

15. |

Insufficient Recognition |

|

16. |

Bad Event |

|

17. |

Mechanical Event |

|

18. |

Meander |

|

19. |

Bad Event |

|

20. |

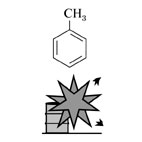

Chemical Phenomenon |

|

21. |

Evaporation/Combustible Gas-air Mixture |

|

22. |

Secondary Damage |

|

23. |

External Damage |

|

24. |

Explosion/Fire |

|

25. |

Loss to Organization |

|

26. |

Economic Loss |

|

27. |

Direct Monetary Damage 200 million yen |

|

|

|

Explosion and fire of toluene excessively contained in paper in the paper-coating process

|

|

Knowledge Comment: |

|

You must teach the properties of chemicals which was used in thd plant to the operators. |

|

|

|

|