| Case Name |

Explosion due to no function of safety equipment in the abnormal reaction during manufacturing phenetidine |

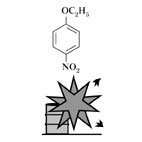

| Pictograph |

|

| Date |

March 9, 1952 |

| Place |

Wakayama prefecture, Japan |

| Location |

Chemical factory |

| Overview |

Explosion occurred at a p-phenetidine manufacturing plant from reduction of p-nitro phenetole. In the usual way, p-nitro phenetole was added to sodium sulfide in the reactor. The temperature rapidly rose due to the unusual reaction. Then, a worker opened the cooling water inlet valve, but the reactor was not cooled. In addition, gas spouted out. The worker tried to operate the manual pressure relief valve after other workers evacuated, but failed and the reactor exploded. The worker who tried a series of emergency procedure was left behind and died. In addition, two workers got injured. |

| Incident |

In the preparation of p-phenetidine plant from the reduction of p-nitro phenetole with sodium sulfide, temperature rapidly rose in the reductive reactor. Opening of the cooling water inlet valve and release operation of the manual pressure relief valve were carried out. However, neither of the valves worked, and temperature and pressure rose, and the reactor exploded. A worker who was operating the valves was left behind and died. In addition, two workers got injured. |

| Processing |

Manufacture |

| Individual Process |

Reaction |

| Process Flow |

Fig3.unit process flow

|

| Chemical Reaction |

Reduction |

| Chemical Equation |

Fig2.chemical reaction formula

|

| Substance |

p-nitro phenetole, Fig4 |

| Type of Accident |

Leakage, explosion |

| Sequence |

The preparation of p-phenetidine was carried out as usual in the following procedure. P-nitro phenetole was added to sodium sulfide at 70 °C in the reactor. Temperature rose to 120 °C - 125 °C spending about one hour. Two chemicals reacted at this temperature for 16 - 17 hours. In the accident, the temperature rose rapidly after the addition of p-nitro phenetole. So the worker opened the cooling water inlet valve. However, the reactor was not cooled. In addition, gas spouted out. The worker tried to release the manual relief valve after other workers evacuated, but the relief valve did not open. Then the reactor exploded during evacuating. |

| Cause |

The reason why the temperature of the reactor rapidly rose is still uncertain. This reactor was a special vessel, and resisting pressure might be insufficient, since authorization and inspection were not carried out. Cooling water facilities for dealing with runaway reaction and a manual pressure relief valve were installed in the plant. However, neither of them functioned, since a daily check was not carried out. |

| Countermeasures |

1. Execution of the pressure test of the reactor.

2. Installation of the automatic relief valve.

3. Execution of a daily check and periodic confirmation of functions of safety facilities.

4. Education and training of the workers. |

| Knowledge Comment |

1. Safety equipment and facilities for the emergency response must be daily checked, and the confirmation of functions must be carried out.

2. The reactor should be constructed with the safety system which can respond to occurring of unusual reaction. |

| Background |

The understanding of the safety management is lacking. |

| Incidental Discussion |

This accident shows the fact that only poor safety measures were made at the time of 1951. |

| Reason for Adding to DB |

Example of accident caused due to defective maintenance of safety facilities and equipment which must operate in the emergency |

| Scenario |

| Primary Scenario

|

Poor Value Perception, Poor Safety Awareness, Inadequate Risk Recognition, Insufficient Analysis or Research, Insufficient Prior Research, Insufficient Pre-Study of Reaction Safety, Reduction Reaction, Planning and Design, Poor Planning, Poor Design, Usage, Maintenance/Repair, Insufficient Observation, Bad Event, Chemical Phenomenon, Abnormal Reaction, Malfunction, Poor Hardware, No Action of Safety Equipment, Secondary Damage, External Damage, Leakage/Explosion, Bodily Harm, Death, Bodily Harm, Injury

|

|

| Sources |

Tamura Masamitsu, Masahide Wakakura, Explosion under phenetidine manufacturing, The reaction hazard., -Accident case and analysis - p. 72(1995).

|

| Number of Deaths |

1 |

| Number of Injuries |

2 |

| Physical Damage |

The reactor was damaged. |

| Financial Cost |

¥ 2 million (the property insurance rate calculation association). |

| Multimedia Files |

Fig4.Chemical formula

|

| Field |

Chemicals and Plants

|

| Author |

OGAWA, Terushige (Graduate School of Environment and Information Sciences, Yokohama National University)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|

|