|

01. |

Poor Value Perception |

|

02. |

Poor Safety Awareness |

|

03. |

Inadequate Risk Recognition |

|

04. |

Insufficient Analysis or Research |

|

05. |

Insufficient Prior Research |

|

06. |

Insufficient Pre-Study of Reaction Safety |

|

07. |

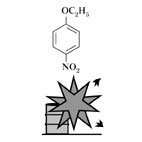

Reduction Reaction |

|

08. |

Planning and Design |

|

09. |

Poor Planning |

|

10. |

Poor Design |

|

11. |

Usage |

|

12. |

Maintenance/Repair |

|

13. |

Insufficient Observation |

|

14. |

Bad Event |

|

15. |

Chemical Phenomenon |

|

16. |

Abnormal Reaction |

|

17. |

Malfunction |

|

18. |

Poor Hardware |

|

19. |

No Action of Safety Equipment |

|

20. |

Secondary Damage |

|

21. |

External Damage |

|

22. |

Leakage/Explosion |

|

23. |

Bodily Harm |

|

24. |

Death |

|

25. |

Bodily Harm |

|

26. |

Injury |

|

|

|

Explosion due to no function of safety equipment in the abnormal reaction during manufacturing phenetidine

|

|

Knowledge Comment: |

|

Overhaul should be done carefully, because safety device must operate surely. |

|

|

|

|