| Case Name |

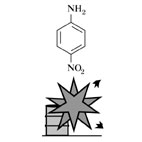

Explosion of the nitroaniline preparation reactor due to error in the quantity of supply of raw materials |

| Pictograph |

|

| Date |

January 1, 1969 |

| Location |

Chemical factory |

| Overview |

In the p-nitroaniline manufacturing plant, a raw material supply pump was changed to a spare pump. The quantity of supply of raw materials changed, pressure and temperature rapidly rose, the reactor burst, and five workers got injured. Releasing the pressure-regulating valve was insufficient, and the safety valve did not operate. In addition, the emergency response of the operators was inadequate. The burst occurred due to these factors. |

| Incident |

At the p-nitroaniline manufacturing plant, a raw material supply pump was switched to a spare pump. As a result, pressure and temperature of the reactor rapidly rose. The reactor burst and five workers got injured. Raw materials were p-nitrochlorobenzene and ammonia. |

| Processing |

Manufacture |

| Individual Process |

Reaction |

| Process Flow |

Fig3.Unit process flow

|

| Chemical Reaction |

Other |

| Chemical Equation |

Fig2.Chemical reaction formula

|

| Substance |

p-nitrochlorobenzene, Fig4 |

| Ammonia, Fig5 |

| p-nitroaniline, Fig6 |

| Type of Accident |

Explosion |

| Sequence |

The raw material supply pump broke down during operation of a plant where p-nitroaniline was manufactured by a reaction of nitrochlorobenzene with ammonia. So, raw materials continued to be supplied by switching to the spare pump. As a result, the feed rate changed automatically, and pressure and temperature rose because the reaction rate increased suddenly. The reactor burst, and five workers got injured. |

| Cause |

It is thought that the accident occurred because the following factors piled in succession.

1. The quantity of supply of raw material was incorrect.

2. Opening of the pressure-regulating valve was insufficient.

3. The safety valve did not operate.

4. The temperature scale of the reactor was inadequate, and temperature over 200 °C could not be confirmed.

5. The operators were not able to take necessary emergency measures. |

| Countermeasures |

1. Education and training to the operators for emergency response are carried out.

2. Maintenance of safety equipment and facilities for emergency use is carried out periodically. |

| Knowledge Comment |

1. The scenario of a runaway reaction was studied, and related factors were eliminated.

2. Safety measures to prevent the reactor from bursting or exploding have been prepared, even if a runaway reaction occurs. |

| Background |

Countermeasure in emergencies were insufficient.

As the data of the accident is insufficient, the cause was not clear. However, following causes might be considered;

1. The main cause might be an error in the feed rate of the raw materials at switching the pumps.

2. Flow measurement and flow control might be insufficient.

3. The basics of operation might be completely disregarded. |

| Reason for Adding to DB |

Example of accident due to insufficient maintenance of safety facilities and emergency equipments |

| Scenario |

| Primary Scenario

|

Poor Value Perception, Poor Safety Awareness, Inadequate Risk Recognition, Insufficient Analysis or Research, Insufficient Practice, Lack of Imagination, Other Reaction, Planning and Design, Poor Planning, Poor Design, Non-Regular Operation, Emergency Operation, Start Spare Machine, Malfunction, Poor System, Abnormal Flow Rate, Bad Event, Chemical Phenomenon, Abnormal Reaction, Secondary Damage, External Damage, Explosion, Bodily Harm, Injury, 5 person injured

|

|

| Sources |

Masamitsu Tamura, Masahide Wakakura, Explosion during nitroaniline generation, Reaction danger -Accident case and analysis -p.132(1995)

|

| Number of Injuries |

5 |

| Physical Damage |

The reactor burst. Most of the manufacturing facilities were damaged. |

| Multimedia Files |

Fig4.Chemical formula

|

|

Fig5.Chemical formula

|

|

Fig6.Chemical formula

|

| Field |

Chemicals and Plants

|

| Author |

OGAWA, Terushige (Graduate School of Environment and Information Sciences, Yokohama National University)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|

|