|

01. |

Poor Value Perception |

|

02. |

Poor Safety Awareness |

|

03. |

Inadequate Risk Recognition |

|

04. |

Insufficient Analysis or Research |

|

05. |

Insufficient Practice |

|

06. |

Lack of Imagination |

|

07. |

Other Reaction |

|

08. |

Planning and Design |

|

09. |

Poor Planning |

|

10. |

Poor Design |

|

11. |

Non-Regular Operation |

|

12. |

Emergency Operation |

|

13. |

Start Spare Machine |

|

14. |

Malfunction |

|

15. |

Poor System |

|

16. |

Abnormal Flow Rate |

|

17. |

Bad Event |

|

18. |

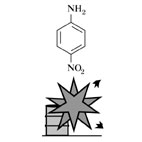

Chemical Phenomenon |

|

19. |

Abnormal Reaction |

|

20. |

Secondary Damage |

|

21. |

External Damage |

|

22. |

Explosion |

|

23. |

Bodily Harm |

|

24. |

Injury |

|

25. |

5 person injured |

|

|

|

Explosion of the nitroaniline preparation reactor due to error in the quantity of supply of raw materials

|

|

Knowledge Comment: |

|

Feed rate change of raw materials is the biggest cauce of the system instability. You must consider from the beginning of design about it. |

|

|

|

|