| Case Name |

Run-away reaction occurred during vacuum distillation of epichlorohydrin waste liquid including dimethylsulfoxide |

| Pictograph |

|

| Date |

November 7, 1990 |

| Place |

Wanouchi, Gifu, Japan |

| Location |

Waste oil recovery factory |

| Overview |

An explosion occurred at distillation facilities where a distillation was carried out at the request of an outside company. Vacuum distillation was carried out to recover ECH from ECH waste oil, which was a mixture of epichlorohydrin (ECH) and dimethylsulfoxide (DMSO). A polymerization reaction began at the bottom of the distillation column, and the temperature rose with the decrease in ECH monomer. In addition, polymerization and decomposition of ECH waste oil were accelerated, because steam heating was continued, and the rapid rising of temperature and pressure led to an explosion and fire. |

| Incident |

An explosion occurred in a distillation unit treating with distillation at the request of another company. While epichlorohydrine (ECH) was being recovered by vacuum distillation from waste oil containing 30% dimethylsulfoxide (DMSO) and 60% ECH from an epoxy resin manufacturing plant, a fire and explosion occurred due to a runaway reaction caused by temperature rising at the bottom. Distilling ECH waste oil was the factory's first experience. |

| Processing |

Manufacture |

| Individual Process |

Distillation |

| Process Flow |

Fig2.Unit process flow

|

| Substance |

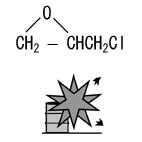

Epichlorohydrin, Fig3 |

| Dimethyl sulfoxide, Fig4 |

| Type of Accident |

Explosion, fire |

| Sequence |

About 08:00 on November 6th, 1990; after the distillation column was evacuated, 70 drum cans (14,000 L) of raw materials were charged.

14:00; the distillation operation started after the pressure reached 100 torrs.

From 07:00 to 07:20; as the safety valve for heating steam actuated, the heating steam pressure was lowered.

07:45; Smoke was generated from a part of the distillation column. An operator notified the office of the smoke. An explosion occurred on his way to the site. Flames spouted out from the manhole, and raw material was scattered. |

| Cause |

A polymerization reaction of ECH occurred, and the composition at the bottom became heavy. Therefore, the temperature at the bottom rose, and polymerization of ECH in the ECH waste oil and decomposition of DMSO, etc. were rapidly accelerated. Due to a pressure increase, raw material blew out, and there was an explosion and fire. An impact spark generated when the lid of the manhole blew off was assumed to be the ignition source. |

| Countermeasures |

Sufficient knowledge of the reaction is necessary. Besides, the contents of impurities are grasped beforehand. |

| Knowledge Comment |

Run-away reaction accidents on distilling waste oil are common. Control of the temperature and pressure, and knowledge of the reaction are necessary. A large-scale unit should be operated after getting sufficient knowledge of the unit after using a small-scale device. |

| Background |

It was the company's first experience to distill recovered ECH, and it is speculated that there was not sufficient recognition of the reaction danger of ECH. Besides, there seemed to be insufficient literature and information collected from other chemical companies of the same kind. Another information source reported that the reaction danger of ECH coexisting with DMSO is much higher than that of ECH alone. Both the distillation company and an ordered company seemed not to have sufficient knowledge about the danger. |

| Incidental Discussion |

There are other examples of accidents with waste oil of an ECH-DMSO system. This system might be a special system. |

| Reason for Adding to DB |

Example of explosion caused due to a runaway reaction from insufficient pre-study on hazards of the first distillation |

| Scenario |

| Primary Scenario

|

Ignorance, Insufficient Knowledge, Insuficient Study and Experience, Poor Value Perception, Poor Safety Awareness, Wrong Risk Recognition, Insufficient Analysis or Research, Insufficient Prior Research, Insufficient Knowledge Characteristics, Planning and Design, Poor Planning, Poor Design, Non-Regular Action, Inaction, No Idea in Next Step, Bad Event, Chemical Phenomenon, Abnormal Reaction, Secondary Damage, External Damage, Explosion, Bodily Harm, Death, Loss to Organization, Economic Loss, Monetary Damage 37 million yen

|

|

| Sources |

The Fire and Disaster Management Agency, Explosion and fire in a distillation kettle of a reduced-pressure distillation unit. Accident examples of dangerous materials. pp.80-82 (1990)

High Pressure Gas Safety Inst. of Japan, The high-pressure gas protection overview, 1991 edition, p.221 (1991).

|

| Physical Damage |

Distillation facilities such as a distillation column, condensers, and pumps were damaged by fire. |

| Financial Cost |

¥ 37 million (Fire and Disaster Management Agency) |

| Multimedia Files |

Fig3.Chemical formula

|

|

Fig4.Chemical formula

|

| Field |

Chemicals and Plants

|

| Author |

KOSEKI, Hirosi (National Research Institute of Fire and Disaster)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|

|