| Case Name |

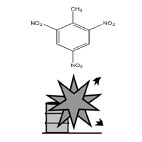

Explosion due to an incompatible reaction in a nitration workroom for TNT |

| Pictograph |

|

| Date |

November 19, 1996 |

| Place |

Edajima, Hiroshima, Japan |

| Location |

Exclusive factory |

| Overview |

A large explosion occurred at a TNT manufacturing plant. The first explosion occurred at a crystallization drum of the refining section. Although some problems occurred from blocked piping due to solidification of the after manufacturing restarted, work was continued. The piping of the sodium carbonate tank was blocked and the valve did not open soon after work started on the morning of the accident. Then, about 1 L of sodium carbonate entered the crystallization drum when the valve was opened for confirmation after piping was heated with steam and blocking was removed. 15-20 kg of TNT from the former batch remained in the crystallization drum. The crystallization drum was heated for about four hours to receive trioil without any treatment. Afterwards, work to receive the trioil into the crystallization drum started. A sound was heard and brown smoke spouted when the drain of the crystallization drum was drained, because the flow rate of oil was half of the usual amount. Smoke gradually became intense and became dark. Flames spouted. Therefore, the workers started to evacuate. The entire plant exploded after a while, and there was a large secondary explosion. The cause was mixing of TNT and sodium carbonate (20% solution) that remained in the crystallization drum, which had changed into a material with a very low initial exothermic temperature due to an incompatible reaction because it was heated for four hours at about 100 °C. A decomposition reaction began because trioil was added. It accelerated and there was an explosion.

In addition, it is presumed that the trioil in the third-order nitration reactor and DNT in the store tank exploded. The basic cause of the accident was insufficient knowledge of hazardous reactions of manufactured materials. |

| Incident |

A large explosion occurred at a TNT manufacturing plant. The first explosion occurred at a crystallization drum of the refinement section. Damage to glass of the denitrification tower was found six days before the accident, and operation of the plant was stopped for five days from the next day. In the morning of the accident day, the piping of the sodium carbonate tank was blocked and the valve did not open soon after manufacturing work began. Then, after the blockage was removed by steam-heating of the valve and piping, the valve was opened for confirmation. As a result, about 1 L of sodium carbonate accumulated in the crystallization drum. Although 15-20 kg of TNT from the former batch remained in the crystallization drum, it was not treated. The crystallization drum was heated by steam for about four hours to receive the trioil. Afterwards, work to receive the trioil into the crystallization drum started. A sound was heard and brown smoke spouted when the drain of the crystallization drum was drained because the oil flow was nearly half of the usual amount. Smoke gradually became intense, and became dark.

Flames spouted. Workers started to escape. The entire plant exploded, and there was a large secondary explosion.

Trioil: A factory term. A liquid for which third-order nitration is finished.

A compound of TNT from which acid is separated, adhering acids, and isomers.

Rough TNT.

Old acid: Old mixed acid for which the nitrification process (nitration) is finished and separated from oil. It is reused in the nitrification process before the stage to recover TNT or DNT that has dissolved.

Third-order old acid: old acid after third-order nitration.

Second-order old acid: old acid after second-order nitration. |

| Processing |

Manufacture |

| Individual Process |

Reaction |

| Process Flow |

Fig2.Unit process flow

|

| Chemical Reaction |

Nitration |

| Chemical Equation |

Fig3.Chemical reaction formula

|

| Substance |

Trinitrotoluene(TNT). Fig4 |

| Nitric acid, Fig5 |

| Sodium carbonate, Fig6 |

| Type of Accident |

Explosion |

| Sequence |

On November 13th, 1996: After work finished, damage to glass of the denitrification tower was found. Repair work was decided to start from the next day by shutting down the plant.

On November 14th to 18th: Repair work was carried out. However, it was interrupted for some reason. So, TNT manufacturing operation was decided to restart from the next day. Steam was made flow into each drum in preparation for restart.

08:15 on November 19th: After preparatory work, mixed acid was poured into the third-order nitration reactor, and the temperature rose to 90 °C. After this, although many problems occurred, charging of raw materials was finished and warm-up operation progressed.

A ring-like crystal was found when the sodium carbonate tank was checked for preparing the crystallization process after starting work. Then, as the valve was checked, it froze and would not open. After melting a sticky material, the valve was opened at 11:00 and about 1 L of sodium carbonate (20% solution) had collected in the crystallization drum.

The tank was heated to 108.5 °C to receive trioil.

At about 14:13: Heating was stopped and trioil was received into the drum. The operator looked into the drum because the amount of NOx generated was less than usual. He found that the flow rate was half of the normal rate.

A sound was heard afterwards and a large amount of NOx was generated. The amount of generated NOx gradually increased, and it changed into dark smoke. A metallic sound was heard afterwards.

As flames of about 30 cm high had been observed from the manhole at the upper part of the drum, the worker sensed danger and escaped to the shelter.

After 1-2 minutes, a large explosion occurred. In addition, a large secondary explosion occurred 2-3 minutes later. |

| Cause |

15-20 kg of TNT from the former batch remained in the crystallization drum. About 1 L (20% solution) of sodium carbonate flowed into the drum, and was heated for four hours at about 100 °C. Contents of the tank changed to a material with a very low initial exothermic temperature due to an incompatible reaction. A decomposition reaction began, accelerated, and exploded because trioil was received. In addition, it is presumed that the trioil in the third-order reactor and DNT in the DNT store tank exploded due to a fire from the explosion. |

| Response |

Having perceived danger, the operators evacuated. |

| Countermeasures |

Strengthening emergency equipment.

Strengthening safety management organization.

Coordinated strengthening of the operation management section and the safety management section.

Strengthening safety education for operators.

Review of a manufacturing safety manual. |

| Knowledge Comment |

When manufacturing and handling hazardous materials, if there is an operation or an incident that is different from usual one, work should be continued after safety is confirmed and there should be sufficient hazard studies. |

| Background |

Knowledge of hazardous reactions of manufactured hazardous materials was insufficient. When a problem occurred, it was solved by a temporary measure without taking fundamental measures. Different operations and different phenomena from usual ones lead to accidents in many cases. Recognition of danger was insufficient. |

| Sequel |

In this factory, the manufacturing system was changed from the past batch system to a continuous system, and production restarted. |

| Reason for Adding to DB |

Example of explosion at a TNT manufacturing plant |

| Scenario |

| Primary Scenario

|

Poor Value Perception, Poor Safety Awareness, Inadequate Risk Recognition, Organizational Problems, Inflexible Management Structure, The Schedule The Prior, Ignorance, Insufficient Knowledge, Insuficient Study, Usage, Maintenance/Repair, Removal of Blockade, Malicious Act, Rule Violation, Safety Rule Violation, Bad Event, Chemical Phenomenon, Generation of Dangerous Sustance, Secondary Damage, External Damage, Explosion, Bodily Harm, Injury, 7 person injured, Loss to Organization, Economic Loss, Factory Damaged Severely, Manetary Damage 850 million yen

|

|

| Sources |

Japan Industrial Safety and Health Assoc. safety and health information center, Case of labor accident, No.100131. Explosion during unusual reaction of explosive refining operation. The Japan Industrial Safety and Health Assoc. home page.

The Japan Industrial Safety and Health Assoc. material. Fire and Disaster Management Agency, TNT nitration workshop explosion, Cases of accidents concerning hazardous materials.1996, pp.126-127.

The C Co. E factory, TNT nitration workshop accident investigation committee, Research report on accident at C Co. E factory TNT nitration workshop. (1997).

|

| Number of Injuries |

8 |

| Physical Damage |

Collapse of 40 buildings (total loss by fire: four), partial collapse of 14 buildings (partial loss by fire: two), partial damage of 65 buildings (partial loss of fire: one), 40.6 ha of a forest burned. |

| Financial Cost |

¥ 846 million. (Fire and Disaster Management Agency) |

| Consequences |

On November 19th, 1966 15:44; An evacuation recommendation was issued to 12 residents within a 1 km radius. |

| Multimedia Files |

Fig4.Chemical formula

|

|

Fig5.Chemical formula

|

|

Fig6.Chemical formula

|

| Field |

Chemicals and Plants

|

| Author |

OGAWA, Terushige (Graduate School of Environment and Information Sciences, Yokohama National University)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|

|