|

01. |

Poor Value Perception |

|

02. |

Poor Safety Awareness |

|

03. |

Inadequate Risk Recognition |

|

04. |

Organizational Problems |

|

05. |

Inflexible Management Structure |

|

06. |

The Schedule The Prior |

|

07. |

Ignorance |

|

08. |

Insufficient Knowledge |

|

09. |

Insuficient Study |

|

10. |

Usage |

|

11. |

Maintenance/Repair |

|

12. |

Removal of Blockade |

|

13. |

Malicious Act |

|

14. |

Rule Violation |

|

15. |

Safety Rule Violation |

|

16. |

Bad Event |

|

17. |

Chemical Phenomenon |

|

18. |

Generation of Dangerous Sustance |

|

19. |

Secondary Damage |

|

20. |

External Damage |

|

21. |

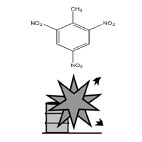

Explosion |

|

22. |

Bodily Harm |

|

23. |

Injury |

|

24. |

7 person injured |

|

25. |

Loss to Organization |

|

26. |

Economic Loss |

|

27. |

Factory Damaged Severely, Manetary Damage 850 million yen |

|

|

|

Explosion due to an incompatible reaction in a nitration workroom for TNT

|

|

Knowledge Comment: |

|

You should prepare the basic countermeasure to do non-regular operation ! Much less, you must not take the allopathic method when you treat very powerful dangerous material like explosives. |

|

|

|

|